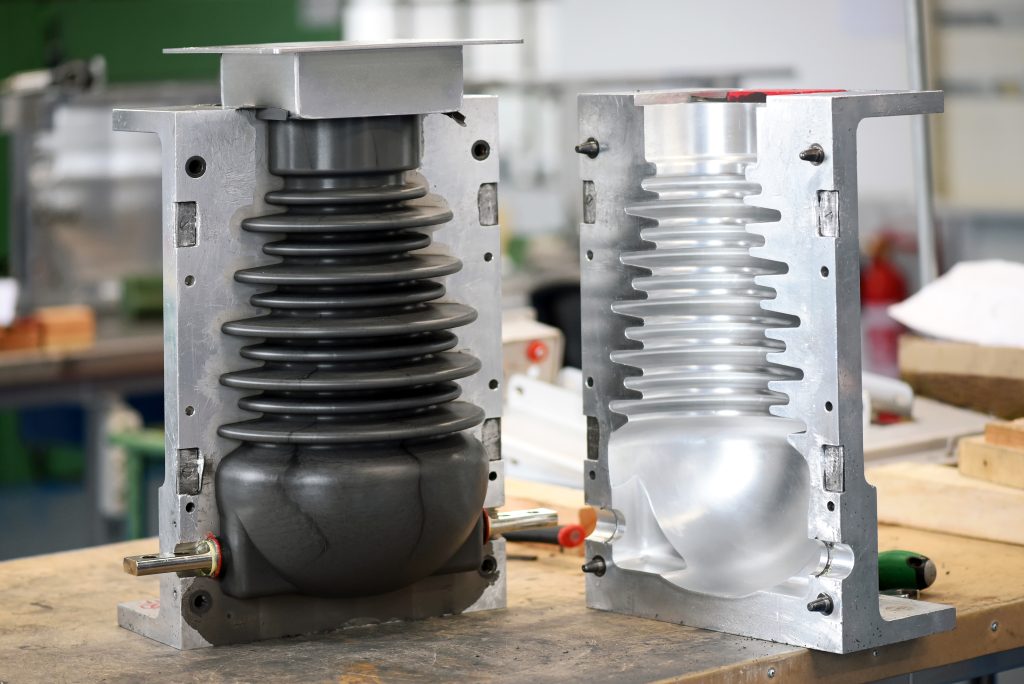

In-House mold making

Setup fees can be a major deterrent when deciding to move forward with a project. KC Seals makes it far more affordable by making all our compression molds in-house, saving you time and money. In addition, your IP stays under one roof and will not get shipped off to another machine shop with which you have no familiarity.