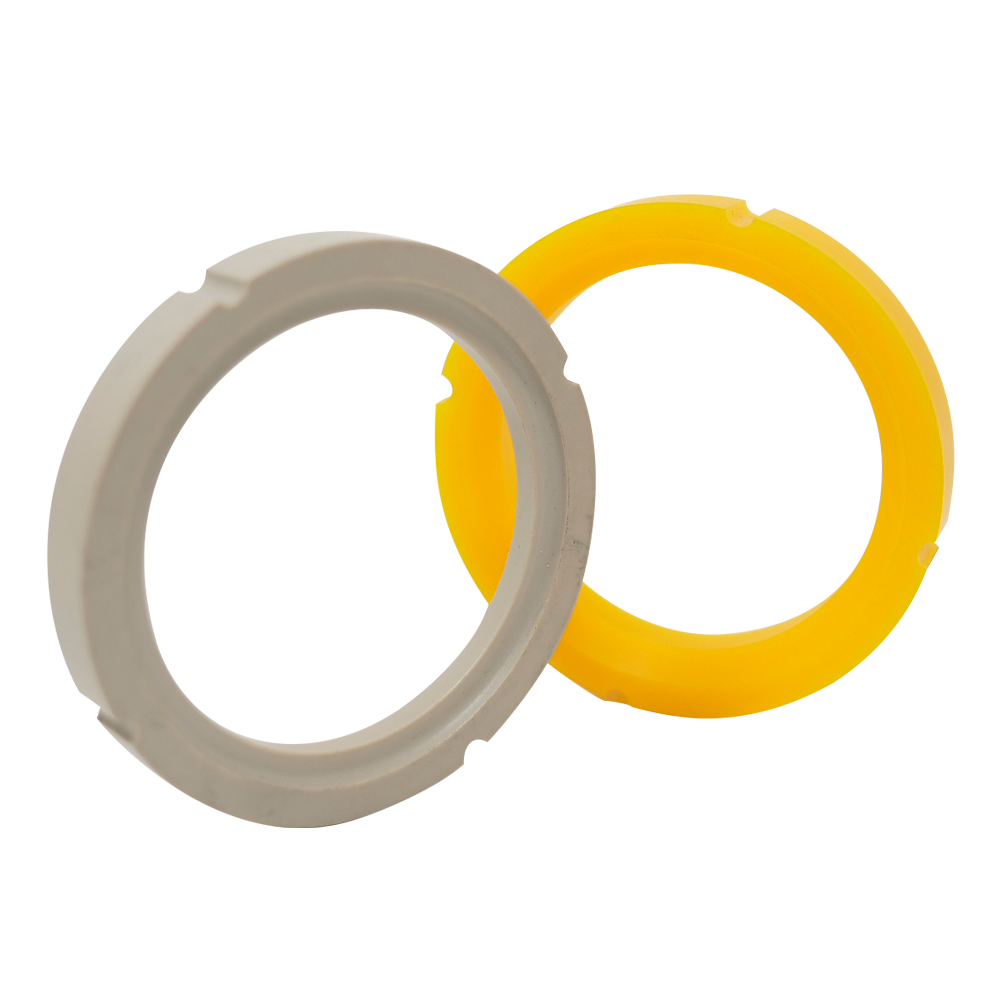

Get quality custom turned and milled rubber or plastic sealing parts in as fast as 1 day

CNC Machining

Book a Meeting

Get quality custom turned and milled rubber or plastic sealing parts in as fast as 1 day

Our CNC manufacturing facility is fully equipped with a variety of CNC machines specifically designed to manufacture rubbers and plastics. We frequently mill and turn complex geometries, this includes elastomer materials. Combined with our digital production system and extensive inventory of rubber and thermoplastic stock shapes, we have the capacity and capabilities to get you your machined sealing products in as fast as today.

For 0ver 20 years we have been turning standard and complex custom sealing parts out of a variety of filled PTFE’s, PEEK’s, Elastomers, and more. Turned products include:

Our basic guidelines for CNC turning include important design considerations to help improve part manufacturability, enhance cosmetic appearance, and reduce overall production time.

| Imperial | Metric | ||

| Maximum Dimensions | Diameter | 12 in. | 305 mm |

| Length | 8 in. | 203 mm | |

| Minimum Dimensions | Diameter | 0.25 in. | 6 mm |

| Length | 0.25 in. | 6 mm | |

| Wall Thickness | 0.020 in. | 0.51 mm | |

| Angle | 30° | 30° | |

| Tolerances | +/- 0.005 in. | +/- 0.127mm | |

Tolerance and dimensions may vary depending on the material. Please contact us for more info info@kcseals.ca

KC Seals offers comprehensive CNC milling services that include all types of 3-axis milling operations. Examples of milling work we do include:

Our basic guidelines for CNC milling include important design considerations to help improve part manufacturability, enhance cosmetic appearance, and reduce overall production time.

| Material | Imperial | Metric | |

| 3-axis | Acetal Nylon PEEK Glass Filled PTFE | 10 in. x 14 in. x 1.75 in. | 254mm x 356mm x 44.5mm |

Tolerances

Typically, KC Seals can hold a machining tolerance of +/- 0.008 in. (0.204mm). Part features are recommended to be thicker than 0.020 in. (0.51mm) in all regions and a nominal part thickness above 0.040 in.

| Material Code | Description | Heat Deflection | Tensile Strength | Elongation | Compressive Strength | Data Sheet |

|---|---|---|---|---|---|---|

| Nylon 66 Natural | General Purpose | 200F | 12000 psi | 50% | 12,500 psi | |

| Nylon 66 Grey | General Purpose | 194F | 12000 psi | 20% | 14,000 psi |

|

| Tecamid 66 HI | Reduced Thermal Degradation | 392F | 10000 psi | 25% | ||

| Tecamid 66 GF30 | 30% Glass Filled | 338F | 13500 psi | 10% | 17,000 psi | |

| Tecamid 612 | Low Moisture | 200F | 10000 psi | 40% | 11,500 psi |

You’ve made it this far, but we know there is still more to discuss. Click on the book a meeting button below to easily setup up a date and time to talk more about your project. You can also email us at info@kcseals.ca