KC Seals began in 1994, when founders Alan and Anne started supplying seals out of a Calgary hydraulic shop. From those humble beginnings, we’ve grown into a specialized sealing manufacturer known for fast turnaround times and uncompromising quality.

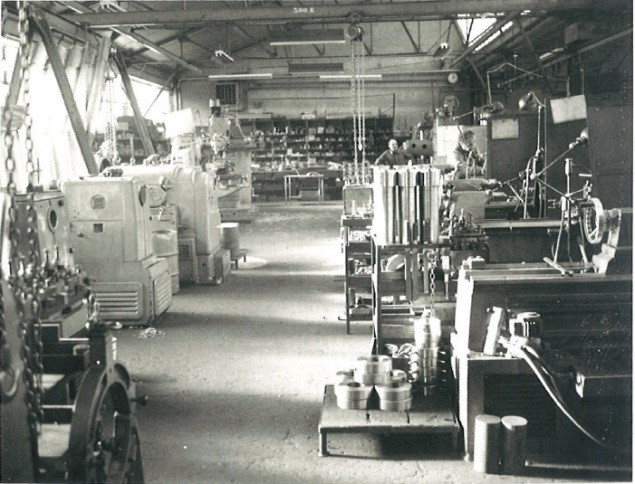

As demand grew, so did our capabilities. We vertically integrated key processes—rubber molding, urethane casting, CNC machining, and in-house mold making—giving us full control over quality and lead time. This flexibility has allowed us to support engineers across North America, Europe, and the Middle East with custom sealing solutions built for performance.

Looking ahead, we’re expanding into the U.S. to better serve our North American clients. This new facility will strengthen our ability to deliver high-performance components—faster than ever.