prevent contaminants such as dirt, dust and moisture from entering the cylinder

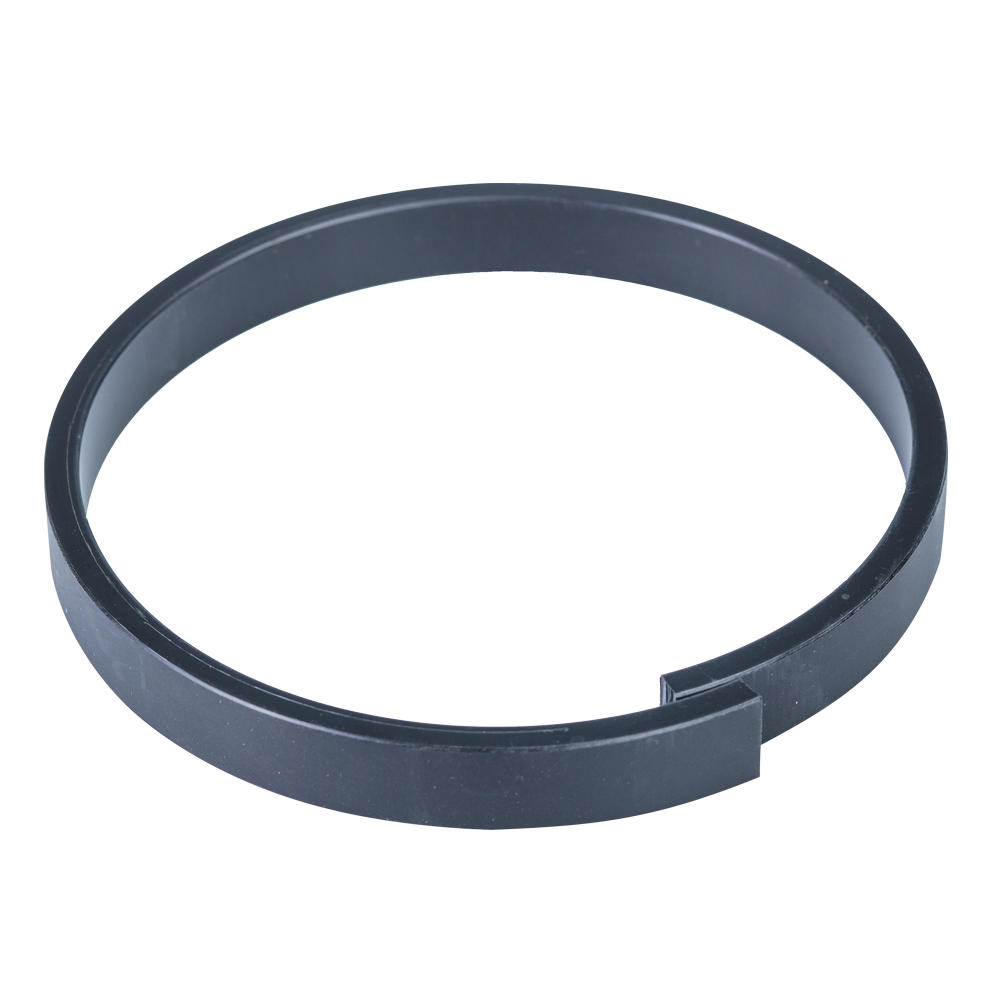

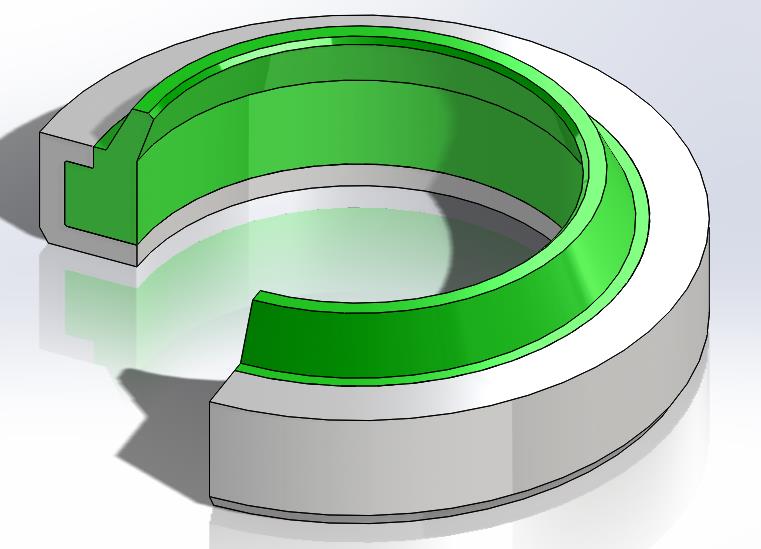

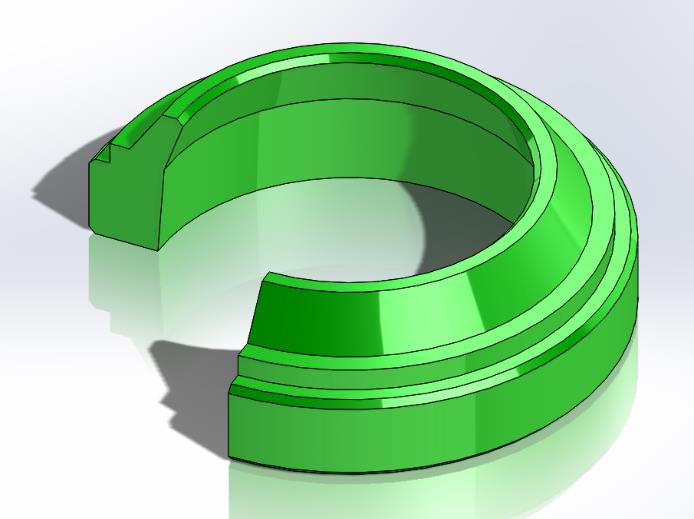

Wipers

prevent contaminants such as dirt, dust and moisture from entering the cylinder

Wipers are installed in the sealing configurations of hydraulic cylinders to prevent contaminants such as dirt, dust and moisture from entering the cylinder as they retract back into the system. Contamination can cause significant damage to the rod, cylinder wall, seals, and other components, and is one of the primary causes of premature seal and component failure in a fluid power system.

All parts are measured on our Zeiss O-Machine and or Keyence CMM, which utilize optical and contact measurement technology in a comprehensive analysis. The O-Machine includes multi-sensor coordinate measuring, white light sensors for non-contact assessments and extremely accurate 3D scanners.

We follow AQL 2.5 levels 1 and 2 sample size quantities, and all molded parts are manufactured to RMA A2 tolerances.

Our rubber and plastic materials supply is diversified amongst the top compounders in North America. Each polymer has been qualified to meet typical exploration and production well conditions, including mechanical, tribological, thermal, and specific immersive properties.

With such a wide range of available materials please contact us to discuss your project. Either click on the Book a meeting button or email us at info@kcseals.ca