Bonded seals represent a significant innovation in the field of industrial sealing. These seals ingeniously combine a metal washer with an elastomeric ring, securely bonded within its diameter, to harness the structural integrity of metal and the flexible sealing capabilities of rubber. This design not only enhances the seal’s effectiveness but also its durability across demanding applications. Principally designed for hydraulic fittings, pipe joints, and under bolt heads, bonded seals are adept at adapting to the tightening process, compressing the elastomer until metal-to-metal contact is achieved, thereby securing the connection and facilitating optimal torque application. The elastomer’s effective retention ensures its function as a pressure-energized seal, similar to that of O-rings and other elastomer seals. Moreover, the concept of the bonded washer has evolved to produce integral seals, sealing plates, or composite seals, designed with elastomer sealing elements integrally molded to metal or plastic retainers, offering precise compression of the elastomer for specific applications. Available in various designs to fit standard thread sizes of bolts and hydraulic fittings, bonded washers highlight the adaptability of bonded seals across a wide range of industrial requirements, underscoring their critical role in modern mechanical engineering and industrial applications.

Bonded seals represent a significant innovation in the field of industrial sealing. These seals ingeniously combine a metal washer with an elastomeric ring, securely bonded within its diameter, to harness the structural integrity of metal and the flexible sealing capabilities of rubber. This design not only enhances the seal’s effectiveness but also its durability across demanding applications. Principally designed for hydraulic fittings, pipe joints, and under bolt heads, bonded seals are adept at adapting to the tightening process, compressing the elastomer until metal-to-metal contact is achieved, thereby securing the connection and facilitating optimal torque application. The elastomer’s effective retention ensures its function as a pressure-energized seal, similar to that of O-rings and other elastomer seals. Moreover, the concept of the bonded washer has evolved to produce integral seals, sealing plates, or composite seals, designed with elastomer sealing elements integrally molded to metal or plastic retainers, offering precise compression of the elastomer for specific applications. Available in various designs to fit standard thread sizes of bolts and hydraulic fittings, bonded washers highlight the adaptability of bonded seals across a wide range of industrial requirements, underscoring their critical role in modern mechanical engineering and industrial applications.

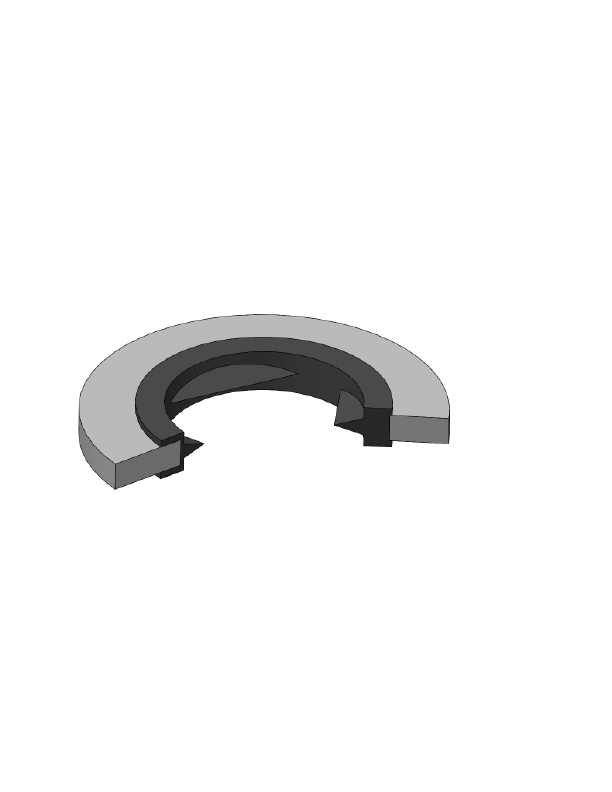

A Fastener Seal is designed with a pre-calculated interference factor built into the teardrop shaped elastomeric seal. The cross section free height of the rubber is greater than the metal retainer, providing the proper compression without squeezing the seal beyond its elastic limit. As the fastener is installed into the mating hardware, the Fastener Seal is compressed down to the retainer thickness. The retainer provides a positive alternate load path for fastener torque and forms a protective gland area for the confinement of the seal in a controlled state. Since the elastomer seal cannot move outward, the mass of the seal is forced inward against the shank of the fastener and against the mating surfaces, creating a positive seal. This principle is known as controlled confinement sealing.

| Part Number | Fastener Size | Thread Diameter | Seal Inner Diameter | Seal Outer Diameter | Outer Diameter | Retainer Thickness |

| BFS 138 | #6 | 0.138 | 0.13 | 0.229 | 0.385 | 0.040 ± 0.004 |

| BFS 164 | #8 | 0.164 | 0.156 | 0.255 | 0.385 | 0.040 ± 0.004 |

| BFS 190 | #10 | 0.19 | 0.18 | 0.317 | 0.443 | 0.050 ± 0.005 |

| BFS 190OS | #10 OS | 0.19 | 0.186 | 0.365 | 0.468 | 0.050 ± 0.005 |

| BFS 250 | 1/4 | 0.25 | 0.24 | 0.381 | 0.505 | 0.050 ± 0.005 |

| BFS 250OS | 1/4 OS | 0.25 | 0.245 | 0.422 | 0.531 | 0.050 ± 0.005 |

| BFS 312 | 1/3 | 0.312 | 0.301 | 0.488 | 0.603 | 0.050 ± 0.005 |

| BFS 375 | 3/8 | 0.375 | 0.364 | 0.546 | 0.666 | 0.050 ± 0.005 |

| BFS 437 | 7/16 | 0.438 | 0.427 | 0.618 | 0.76 | 0.050 ± 0.005 |

| BFS 500 | 1/2 | 0.5 | 0.49 | 0.696 | 0.88 | 0.050 ± 0.005 |

| BFS 562 | 9/16 | 0.562 | 0.552 | 0.759 | 1.067 | 0.050 ± 0.005 |

| BFS 625 | 5/8 | 0.625 | 0.615 | 0.818 | 1.193 | 0.050 ± 0.005 |

| BFS 688 | 11/16 | 0.688 | 0.674 | 0.898 | 1.26 | 0.050 ± 0.005 |

| BFS 750 | 3/4 | 0.75 | 0.74 | 0.982 | 1.322 | 0.064 ± 0.005 |

| BFS 812 | 13/16 | 0.812 | 0.798 | 1.048 | 1.416 | 0.064 ± 0.005 |

| BFS 875 | 7/8 | 0.875 | 0.864 | 1.105 | 1.51 | 0.064 ± 0.005 |

| BFS 938 | 15/16 | 0.938 | 0.921 | 1.172 | 1.635 | 0.064 ± 0.005 |

| BFS 1000 | 1 | 1 | 0.988 | 1.234 | 1.76 | 0.064 ± 0.005 |

| BFS 1062 | 1 1/16 | 1.063 | 1.05 | 1.29 | 1.822 | 0.064 ± 0.005 |

| BFS 1125 | 1 1/18 | 1.125 | 1.106 | 1.351 | 1.885 | 0.064 ± 0.005 |

| BFS 1188 | 1 3/16 | 1.188 | 1.167 | 1.442 | 1.947 | 0.064 ± 0.005 |

| BFS 1250 | 1 1/4 | 1.25 | 1.229 | 1.474 | 2.01 | 0.064 ± 0.005 |

| BFS 1312 | 1 5/16 | 1.313 | 1.29 | 1.567 | 2.072 | 0.064 ± 0.005 |

| BFS 1375 | 1 3/8 | 1.375 | 1.352 | 1.631 | 2.135 | 0.064 ± 0.005 |

| BFS 1438 | 1 7/16 | 1.438 | 1.413 | 1.693 | 2.197 | 0.064 ± 0.005 |

| BFS 1500 | 1 1/2 | 1.5 | 1.475 | 1.817 | 2.26 | 0.091 ± 0.005 |

| BFS 1625 | 1 5/8 | 1.625 | 1.6 | 1.942 | 2.385 | 0.091 ± 0.005 |

| BFS 1750 | 1 3/4 | 1.75 | 1.725 | 2.067 | 2.51 | 0.091 ± 0.005 |

| BFS 1875 | 1 7/8 | 1.875 | 1.85 | 2.192 | 2.635 | 0.091 ± 0.005 |

| BFS 2000 | 2 | 2 | 1.975 | 2.317 | 2.76 | 0.091 ± 0.005 |

| BFS 3000 | 3 | 3 | 2.975 | 3.43 | 5.5 | 0.120 ± 0.005 |

Thread Seals present a robust and efficient sealing solution for threaded connections, tailored to meet the precise demands of mechanical engineers. Characterized by their self-centering and non-directional design, these seals engage directly with thread contours, eliminating the need for specialized fasteners or fittings. This inherent design simplicity facilitates significant cost efficiencies by permitting the use of standard, readily available fastening components. Installation is straightforward and intuitive, requiring no specialized tools or training—simply affix the seal with a gentle twisting action and secure the fastener.

In their operational design, Thread Seals obstruct potential leakage paths within threaded assemblies. Typically positioned on the nut side of a fastener, they address the additional spiral leakage path presented by thread helices. The seal features three wedge-shaped internal protrusions, designed to interact with the singular V-shaped channel of standard screw threads, effectively blocking fluid migration.

Installation guidelines emphasize the importance of ensuring the rubber element is fully encompassed by adjacent metal components to prevent extrusion. The design necessitates a minimum flat surface area on the nut or washer to achieve this coverage. Additionally, since rubber cannot be compressed, it requires a designated void to accommodate displacement under load. This void is achieved through a clearance hole or, alternatively, a washer or counterbore to facilitate proper seating and performance of the seal. For applications involving adjustment screws, an NAS 20002 countersunk cover washer is recommended. While lubrication is not essential for the installation of Thread Seals, if used, compatibility with the selected elastomer is paramount.

| Part Number | UNC (Coarse) | UNF (Fine) | Outer Diameter | Retainer Thickness | Clearance Diameter | Minimum diameter of mating surface | Bore Depth |

| BTS 006 | 32 | 40 | 0.406 | 0.05 | 0.143/0.149 | 3/8 | 3/64 |

| BTS 008 | 32 | 36 | 0.406 | 0.05 | 0.170/0.177 | 3/8 | 3/64 |

| BTS 010 | 24 | 32 | 0.469 | 0.05 | 0.198/0.206 | 3/8 | 1/16 |

| BTS 012 | 24 | 28 | 0.562 | 0.05 | 0.224/0.234 | 7/16 | 1/16 |

| BTS 250 | 20 | 28 | 0.562 | 0.05 | 0.260/0.271 | 7/16 | 1/16 |

| BTS 312 | 18 | 24 | 0.687 | 0.064 | 0.327/0.339 | 1/2 | 1/16 |

| BTS 375 | 16 | 24 | 0.75 | 0.064 | 0.392/0.406 | 5/8 | 1/16 |

| BTS 437 | 14 | 20 | 0.906 | 0.078 | 0.458/0.474 | 11/16 | 1/16 |

| BTS 500 | 13 | 20 | 1 | 0.078 | 0.523/0.541 | 3/4 | 1/16 |

| BTS 562 | 12 | 18 | 1.094 | 0.094 | 0.589/0.609 | 7/8 | 1/16 |

| BTS 625 | 11 | 18 | 1.187 | 0.094 | 0.654/0.676 | 1 | 1/16 |

| BTS 750 | 10 | 16 | 1.375 | 0.109 | 0.788/0.812 | 1 1/8 | 3/32 |

| BTS 875 | 9 | 14 | 1.562 | 0.109 | 0.921/0.947 | 1 1/4 | 3/32 |

| BTS 1000 | 8 | 12 | 1.75 | 0.12 | 1.054/1.082 | 1 7/16 | 3/32 |

| BTS 1125 | 8* | 12 | 1.875 | 0.12 | 1.187/1.217 | 1 9/16 | 3/16 |

| BTS 1250 | 8* | 12 | 2 | 0.12 | 1.321/1.353 | 1 11/16 | 3/16 |

| BTS 1375 | 8* | 12 | 2.125 | 0.12 | 1.454/1.488 | 1 13/16 | 3/16 |

| BTS 1500 | 8* | 12 | 2.25 | 0.12 | 1.587/1.623 | 1 15/16 | 3/16 |

| BTS 1750 | 5 | N/A | 3.375 | 0.179 | 1.865/1.920 | 2 7/16 | 3/8 |

Originally developed as an advanced alternative to traditional copper washers in high-pressure environments, the 400 series bonded seal represents a significant innovation in sealing technology. This seal integrates a metal washer with an elastomeric ring securely bonded within its diameter. The design ingeniously combines the structural integrity of the metal washer, which acts to prevent over-compression, with the flexibility of the elastomeric ring, ensuring it remains within its optimal deformation limits. This synergy not only enhances the seal’s effectiveness but also its durability in demanding applications.

| Part Number | Bolt Size | O.D. | I.D. | Metal Thickness | Total Height |

| BBW 250 | 1/4 | 0.52 | 0.27 | 0.051 | 0.074 |

| BBW 312 | 5/16 | 0.56 | 0.34 | 0.051 | 0.074 |

| BBW 375 | 3/8 | 0.625 | 0.408 | 0.083 | 0.113 |

| BBW 437 | 7/16 | 0.75 | 0.46 | 0.083 | 0.113 |

| BBW 500 | 1/2 | 0.81 | 0.541 | 0.083 | 0.113 |

| BBW 562 | 9/16 | 0.875 | 0.585 | 0.083 | 0.113 |

| BBW 625 | 5/8 | 1 | 0.65 | 0.083 | 0.113 |

| BBW 687 | 11/16 | 1 | 0.715 | 0.097 | 0.127 |

| BBW 750 | 3/4 | 1.06 | 0.775 | 0.097 | 0.127 |

| BBW 812 | 13/16 | 1.125 | 0.848 | 0.097 | 0.127 |

| BBW 875 | 7/8 | 1.25 | 0.925 | 0.097 | 0.127 |

| BBW 1000 | 1 | 1.375 | 1.065 | 0.097 | 0.127 |

| BBW 1062 | 1 1/16 | 1.52 | 1.095 | 0.097 | 0.127 |

| BBW 1187 | 1 3/16 | 1.5 | 1.213 | 0.097 | 0.127 |

| BBW 1312 | 1 5/16 | 1.685 | 1.334 | 0.133 | 0.163 |

| BBW 1375 | 1 3/8 | 1.75 | 1.415 | 0.133 | 0.163 |

| BBW 1500 | 1 1/2 | 1.88 | 1.534 | 0.133 | 0.163 |

| BBW 1625 | 1 5/8 | 2.062 | 1.69 | 0.133 | 0.163 |

| BBW 1750 | 1 3/4 | 2.25 | 1.905 | 0.133 | 0.163 |

| BBW 1875 | 1 7/8 | 2.307 | 1.907 | 0.133 | 0.163 |

| BBW 2125 | 2 1/8 | 2.75 | 2.161 | 0.133 | 0.163 |

| BBW 2250 | 2 1/4 | 2.77 | 2.285 | 0.133 | 0.163 |