Get quality custom turned and milled rubber or plastic sealing parts in as fast as 1 day

Custom Machined Products

Book a Meeting

Get quality custom turned and milled rubber or plastic sealing parts in as fast as 1 day

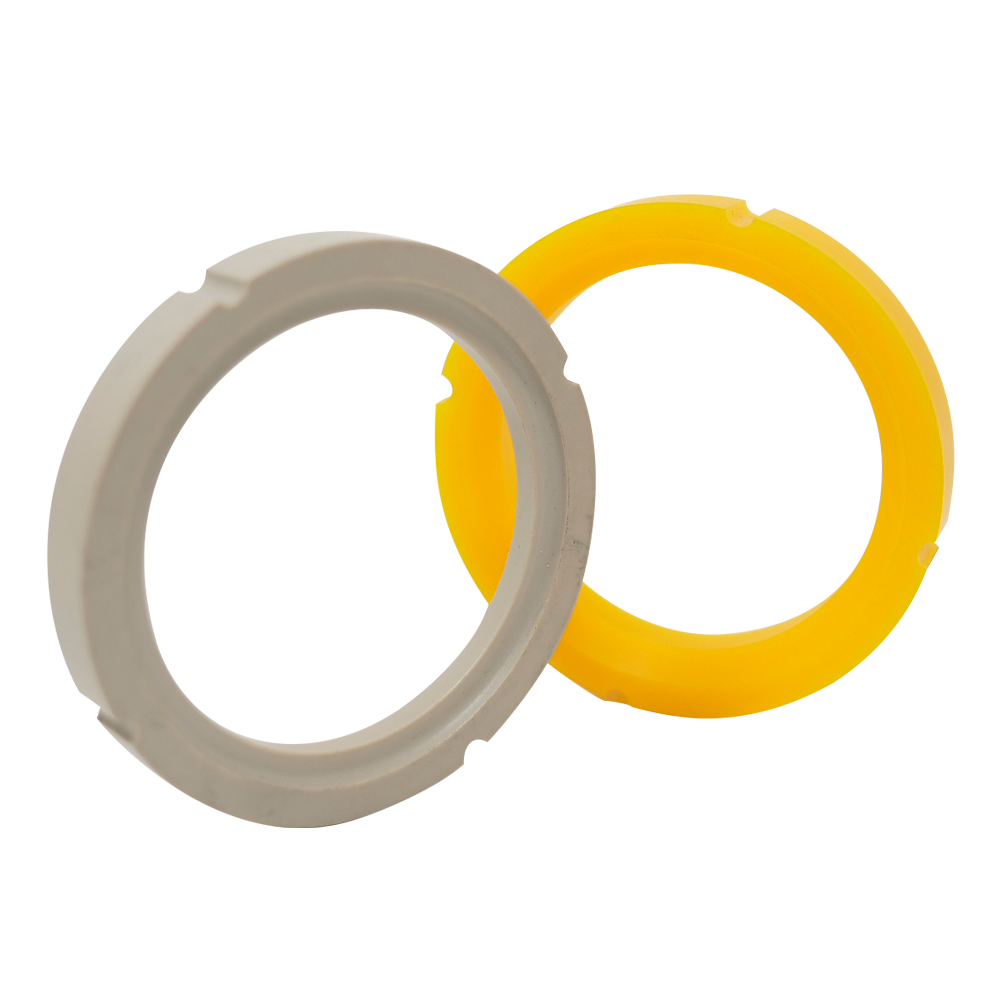

At KC Seals, we excel in CNC machining, specifically tailored to the unique demands of rubber and plastic materials. Our advanced capabilities encompass both CNC turning and CNC milling, enabling us to produce complex sealing components with unparalleled precision and efficiency. In addition, our CNC machines and tooling are specifically procured and designed to handle a variety of materials, including PTFE, PEEK, Polyimides, various elastomers, and more, ensuring that we meet the diverse needs of our engineering clients.

Choosing the right plastic or rubber material for CNC machining is critical, as each material has unique properties that influence its machinability and suitability for specific applications. For example, polycarbonate is prized for its high clarity and impact resistance, making it ideal for transparent applications, while nylon is valued for its strength and toughness, suitable for load-bearing components. At KC Seals, we leverage our deep understanding of these materials to select the best options for your project, ensuring optimal performance and longevity of the final product.

Our expertise in CNC machining extends beyond just material selection. We understand the intricacies involved in machining plastics and rubber, which are generally less rigid than metals and can deform under excessive heat and pressure. Our skilled machinists employ specialized tooling and techniques to manage these challenges effectively, using precise machining parameters to achieve tight tolerances and minimize material deformation. This precision is particularly vital in industries such as aerospace, medical devices, and microelectronics, where exact specifications are critical.

Additionally, KC Seals is equipped to handle complex geometries that might be difficult or impossible to achieve with other manufacturing methods. Our CNC machining allows for the creation of intricate designs with high repeatability and consistency, which is essential for both prototyping and large-scale production of custom parts. Our rapid turnaround times, often as quick as one day, cater to the urgent needs of mechanical engineers who require precision and reliability in their components.

Partnering with KC Seals means you are working with a team that combines extensive experience, advanced technology, and a deep understanding of material properties to deliver the best CNC machined rubber and plastic components in the industry. Trust us to provide the precision, efficiency, and expertise that your projects demand.

You’ve made it this far, but we know there is still more to discuss. Click on the book a meeting button below to easily setup up a date and time to talk more about your project. You can also email us at info@kcseals.ca

At KC Seals, we excel in CNC machining, specifically tailored to the unique demands of rubber and plastic materials. Our advanced capabilities encompass both CNC turning and CNC milling, enabling us to produce complex sealing components with unparalleled precision and efficiency. In addition, our CNC machines and tooling are specifically procured and designed to handle a variety of materials, including PTFE, PEEK, Polyimides, various elastomers, and more, ensuring that we meet the diverse needs of our engineering clients.

Choosing the right plastic or rubber material for CNC machining is critical, as each material has unique properties that influence its machinability and suitability for specific applications. For example, polycarbonate is prized for its high clarity and impact resistance, making it ideal for transparent applications, while nylon is valued for its strength and toughness, suitable for load-bearing components. At KC Seals, we leverage our deep understanding of these materials to select the best options for your project, ensuring optimal performance and longevity of the final product.

Our expertise in CNC machining extends beyond just material selection. We understand the intricacies involved in machining plastics and rubber, which are generally less rigid than metals and can deform under excessive heat and pressure. Our skilled machinists employ specialized tooling and techniques to manage these challenges effectively, using precise machining parameters to achieve tight tolerances and minimize material deformation. This precision is particularly vital in industries such as aerospace, medical devices, and microelectronics, where exact specifications are critical.

Additionally, KC Seals is equipped to handle complex geometries that might be difficult or impossible to achieve with other manufacturing methods. Our CNC machining allows for the creation of intricate designs with high repeatability and consistency, which is essential for both prototyping and large-scale production of custom parts. Our rapid turnaround times, often as quick as one day, cater to the urgent needs of mechanical engineers who require precision and reliability in their components.

Partnering with KC Seals means you are working with a team that combines extensive experience, advanced technology, and a deep understanding of material properties to deliver the best CNC machined rubber and plastic components in the industry. Trust us to provide the precision, efficiency, and expertise that your projects demand.

For 0ver 20 years we have been turning standard and complex custom sealing parts out of a variety of filled PTFE’s, PEEK’s, Elastomers, and more. Turned products include:

Our basic guidelines for CNC turning include important design considerations to help improve part manufacturability, enhance cosmetic appearance, and reduce overall production time.

| Imperial | Metric | ||

| Maximum Dimensions | Diameter | 12 in. | 305 mm |

| Length | 8 in. | 203 mm | |

| Minimum Dimensions | Diameter | 0.25 in. | 6 mm |

| Length | 0.25 in. | 6 mm | |

| Wall Thickness | 0.020 in. | 0.51 mm | |

| Angle | 30° | 30° | |

| Tolerances | +/- 0.005 in. | +/- 0.127mm | |

Tolerance and dimensions may vary depending on the material. Please contact us for more info info@kcseals.ca

KC Seals offers comprehensive CNC milling services that include all types of 3-axis milling operations. Examples of milling work we do include:

Our basic guidelines for CNC milling include important design considerations to help improve part manufacturability, enhance cosmetic appearance, and reduce overall production time.

| Material | Imperial | Metric | |

| 3-axis | Acetal Nylon PEEK Glass Filled PTFE | 10 in. x 14 in. x 1.75 in. | 254mm x 356mm x 44.5mm |

Tolerances

Typically, KC Seals can hold a machining tolerance of +/- 0.008 in. (0.204mm). Part features are recommended to be thicker than 0.020 in. (0.51mm) in all regions and a nominal part thickness above 0.040 in.

| Material Code | Description | Heat Deflection | Tensile Strength | Tensile Elongation | Compressive Strength |

| PEEK | Victrex 450G PEEK. Good toughness and impact performance, with high elongation properties. Certified to ISO 23936/NORSOK M-710 for high sour fluid ageing. | 305F | 14300 psi | 45.0% | 18100 psi |

| GPEEK | Victrex 450GL30 PEEK. Same features as virgin PEEK, but with higher tensile strength, as well as increased shear strength. Certified to ISO 23936/NORSOK M-710 for high sour fluid ageing. | 620F | 26000 psi | 2.7% | 37000 psi |

| P5030 | Bearing Grade PEEK | 530F | 8000 psi | 2.5% | 13000 psi |

| P5045 | PTFE Filled PEEK | 300F | 9500 psi | 7.0% | 12800 psi |

| P5035 | Lubricated PEEK | 530F | 11000 psi | 3.6 % | 18100 psi |

| Material Code | Description | Heat Deflection | Tensile Strength | Tensile Elongation | Compressive Strength |

| CFP | Carbon Fiber Filled PTFE– (polytetrafluorethylene) material. It exhibits improved creep and wear resistance. Increased thermal conductivity and low coefficient of friction ensure low wear rate even under dry running conditions. It is suitable for gaskets, valve seals, packings, bearings, and piston rings. | 150°F | 1600 psi | 50.0 % | 1300 psi |

| GFP | Glass-fibre Filled PTFE. Glass-fibre improves the wear properties of PTFE, lowers the deformation under load at both high and low temperatures, and increases the impact resistance while leaving the electrical and chemical characteristics of PTFE essentially unchanged. It is suitable for piston rings, valve seats, shaft seals, electrical insulators, bearing pads and gaskets. This material should not be used in contact with strong alkalis and hydrofluoric acid. | 150 °F | 1750 psi | 175.0 % | 2600 psi |

| MGFP | MolyGlass PTFE– a glass fiber and molybdenum disulfide filled polytetrafluorethylene (PTFE). It is used for bushings, bearings, and sealing elements where low creep properties with good sealability and low wear rates are desirable. | 150 °F | 3600 psi | 200.0% | 1800 psi |

| CGTP | Carbon-graphite Filled PTFE (polytetrafluorethylene) material. Its ability to run under dry or wet conditions along with its low wear rate makes it an ideal high-temperature bearing material. It also offers high load-bearing capability, relative to other fluoropolymers, for many general-purpose industrial applications. | 150 °F | 2300 psi | 105.0 % | 2500 psi |

| BFP | Bronze-filled PTFE (polytetrafluoroethylene). It provides better creep resistance than most of the PTFE alloys. It possesses high compressive strength and good wear and sliding properties. Most common applications include piston rings (compressors), bushes, bearings, and wear pads for high compression sliding applications. Certain chemicals may easily attack bronze. | 175 °F | 2000 psi | 100.0 % | 1700 psi |

| MFP | Mica-filled PTFE (polytetrafluorethylene) material. It exhibits very low coefficient of friction and low wear rate under dry running conditions. It is an ideal non-abrasive sealing material against soft metal surfaces in dynamic applications. Compared with other filled PTFE materials, it exhibits excellent sealability at high temperatures. It offers excellent dimensional stability, unparalleled chemical resistance and continuous use temperature of 500 oF. | 210 °F | 2200 psi | 250.0 % | 3000 psi |

| 1130 | 1130 is a polymer and carbon-filled PTFE (polytetrafluorethylene) material that is significantly softer than VERTEC 1030, but it is a much better sealing material with good wear properties. This material has excellent tensile strength and elongation for PTFE-based materials. This material is specifically designed for demanding sealing/wear applications where PTFE is deemed appropriate. | 150 °F | 2700 psi | 60.0 % | 1500 psi |

| Material Code | Description | Heat Deflection | Tensile Strength | Elongation | Compressive Strength |

|---|---|---|---|---|---|

| ACGP100 | General-purpose FDA and Canada AG compliant. | 220F | 9500 psi | 30% | 15,000 psi |

| ACDL100 | Delrin® is low friction, long wear, PTFE/acetal blend | 244F | 8000 psi | 15% | 16,000 psi |

| Material Code | Description | Heat Deflection | Tensile Strength | Elongation | Compressive Strength |

|---|---|---|---|---|---|

| Nylon 66 Natural | General Purpose | 200F | 12000 psi | 50% | 12,500 psi |

| Nylon 66 Grey | General Purpose | 194F | 12000 psi | 20% | 14,000 psi |

| Tecamid 66 HI | Reduced Thermal Degradation | 392F | 10000 psi | 25% | |

| Tecamid 66 GF30 | 30% Glass Filled | 338F | 13500 psi | 10% | 17,000 psi |

| Tecamid 612 | Low Moisture | 200F | 10000 psi | 40% | 11,500 psi |

| Material Code | Description | Heat Deflection | Tensile Strength | Elongation | Compressive Strength |

|---|---|---|---|---|---|

| PI6000 | Unfilled PI | 680F | 11,500 psi | 7.5% | 16,000 psi |

| PI6011 | Moly Filled PI | 680F | 7500 psi | 3.0% | 18,000 psi |

| PI6098 | Lubricated PI | 680F | 10,000 psi | 1.0% | 15,000 psi |

| Material Code | Description | Heat Deflection | Tensile Strength | Elongation | Compressive Strength |

|---|---|---|---|---|---|

| P7010 | Glass Filled PPS | 490F | 6700 psi | 1.0% | 23,800 psi |

| P7017 | PTFE Filled PPS | 475F | 10500 psi | 2.0% | 15,000 psi |

| P7023 | Bearing Grade PPS | 490F | 7500 psi | 1.5% | 15,000 psi |

| Material Code | Application | Description | Temperature Range |

| NBR-WE130-B | General Purpose Nitrile (NBR, Buna) 80 Durometer | NBR 80 (Nitrile Butadiene Rubber), also known as Buna-N, is a versatile, cost-effective material widely used for general-purpose applications. It offers robust mechanical properties and basic resistance to many lubricants. NBR 80 performs well in applications needing FDA compliance and metal detectability, with good to excellent resistance to compression set, tear, abrasion, and substances like petroleum oils, hydraulic fluids, alcohol, water, silicone greases, Di-ester lubricants, and ethylene-glycol based fluids. It has a service temperature range of -30 to 250°F and meets ASTM 2000 M2BG710 specifications. However, it is not suitable for environments with ozone, UV, weathering, certain fuels, and solvents. For specific compound formulations, consulting with engineering is recommended. | -35°C to 120°C (-30°F to 250°F) |

| NBR93100-B | General Purpose Nitrile (NBR, Buna) 90 Durometer | NBR 90 (Nitrile Butadiene Rubber with a durometer hardness of 90 Shore A) is a highly durable material suited for demanding applications requiring resistance to wear, deformation, and mechanical stress. It excels in environments with oils, fuels, and various chemicals, maintaining integrity under high pressure and mechanical loads due to its superior load-bearing capacity and dimensional stability. However, NBR 90 is not suitable for exposure to ozone, UV, weathering, certain fuels, and solvents. For optimal performance, consulting with engineering for the appropriate compound formulation is recommended. NBR 90 is ideal for applications needing high durability and mechanical strength in industrial settings. | -35°C to 120°C (-30°F to 250°F) |

| HSN83002-B | General Purpose Hydrogenated Nitrile Butadiene Rubber (HSN, HNBR) 80 Durometer | HNBR 80 is a high-performance synthetic rubber known for its excellent resistance to heat, chemicals, and mechanical stress. Created by hydrogenating NBR, it offers enhanced durability against degradation from heat, oil, and chemical exposure. HNBR 80 is ideal for demanding applications, providing superior resistance to petroleum-based oils, fuels, aliphatic hydrocarbons, silicone oils, greases, and ethylene glycol. It also withstands hot water, steam, and diluted acids and bases, operating effectively from -40°F to 325°F. The harder durometer increases durability and load-bearing capacity, making it perfect for high-pressure applications, with improved abrasion and extrusion resistance for longer service life. However, it should be avoided in environments with highly polar solvents like acetone, ozone, UV, and weathering conditions. HNBR 80 is a cost-effective alternative to more expensive fluorocarbon elastomers, commonly used in automotive, industrial, and oil and gas applications. | -40°C to 150°C (-40°F to 302°F) |

| HSN93001-B | General Purpose Hydrogenated Nitrile Butadiene Rubber (HSN, HNBR) 90 Durometer | HNBR 90 (Hydrogenated Nitrile Butadiene Rubber with a durometer hardness of 90 Shore A) is a high-performance material known for its exceptional durability and resistance to heat, chemicals, and mechanical stress. It excels in applications involving petroleum-based oils, fuels, aliphatic hydrocarbons, silicone oils, and greases. Operating effectively from -40°F to 325°F, its increased hardness provides superior abrasion and extrusion resistance, ideal for heavy-duty uses. Not recommended for highly polar solvents and ozone, HNBR 90 is widely used in automotive, industrial, and oil and gas sectors. | -40°C to 150°C (-40°F to 302°F) |

| MCM3008-B | Swell Resistant HNBR 80 Durometer | MCM3008 is an advanced 80 durometer Hydrogenated Nitrile Butadiene Rubber (HNBR) compound specifically formulated for applications requiring exceptional chemical resistance and durability. The peroxide curing process enhances its resistance to high temperatures and aggressive chemicals, making it ideal for use in harsh drilling environments, such as oil-based muds (OBMs), inverts, and brines. This compound’s notable feature is its exceptional swell resistance, which ensures reliable performance and longevity even when exposed to various fluids commonly encountered in drilling operations. With a high tensile strength of approximately 4000 psi, MCM3008 demonstrates superior robustness and mechanical strength, essential for maintaining integrity under challenging conditions. | -35°C to 160°C (-30°F to 320°F) |

| MCM3009-B | Swell Resistant HNBR 90 Durometer | MCM3009, a 90 durometer HNBR compound, is a peroxide-cured material engineered for high chemical resistance and superior performance in demanding environments such as oil-based muds (OBMs), inverts, and brines common in drilling applications. This HNBR compound is known for its exceptional swell resistance in various fluids and boasts a high tensile strength exceeding 4000 psi, highlighting its robustness. With a service temperature range of -35°C to 160°C (-30°F to 320°F), MCM3009 is an outstanding choice for applications requiring strength, durability, and chemical resilience. | -35°C to 160°C (-30°F to 320°F) |

| 15760-B | Extrusion Resistant HNBR (HSN)

| The 15760-B is a newly developed 90+ durometer HNBR compound specifically designed for exceptional extrusion resistance. Its high durometer of 90+ Shore A contributes to its rigidity, significantly reducing deformation and preventing extrusion into gaps and clearances. Additionally, with a high modulus of elasticity, the 15760-B exhibits superior stiffness, further enhancing its resistance to mechanical deformation. While the optimized formulation includes specific fillers that increase the compound’s mechanical strength and stability. This combination ensures that 15760-B maintains its integrity under extreme conditions, making it an ideal choice for demanding applications in the oil and gas industry. | −450°F to 500°F (−270°C to 260°C) |

| 354260-B

| API 11D1 Approved HNBR (HSN) 80 Durometer

| The 354260-B compound, an HNBR material with an 80 durometer hardness, has successfully passed rigorous testing under conditions corresponding to API 11D1 V3, and V0 grades. This API standard encompasses stringent requirements for downhole equipment, specifically focusing on packer elements and other sealing components used in the oil and gas industry. Achieving V3 and V0 grade certifications under API 11D1 indicates that this HNBR material possesses exceptional mechanical properties and durability, demonstrating a remarkable capacity for maintaining seal integrity even under the high-pressure and high-temperature conditions typical of downhole environments. The ability of the 354260-B compound to operate effectively across a wide temperature range of -35°C to 160°C (-30°F to 320°F) further emphasizes its adaptability and resilience. The successful adherence to such a reputable standard is a testament to the compound’s superior quality, making it a formidable choice for critical applications in the demanding field of oil and gas extraction and production. | -35°C to 160°C (-30°F to 320°F)

|

| 115881-B

| API 11D1 Approved HNBR (HSN) 90 Durometer

| The 354260-B compound, an HNBR material with an 90 durometer hardness, has successfully passed rigorous testing under conditions corresponding to API 11D1 V3, and V0 grades. This API standard encompasses stringent requirements for downhole equipment, specifically focusing on packer elements and other sealing components used in the oil and gas industry. Achieving V3 and V0 grade certifications under API 11D1 indicates that this HNBR material possesses exceptional mechanical properties and durability, demonstrating a remarkable capacity for maintaining seal integrity even under the high-pressure and high-temperature conditions typical of downhole environments. The ability of the 354260-B compound to operate effectively across a wide temperature range of -35°C to 160°C (-30°F to 320°F) further emphasizes its adaptability and resilience. The successful adherence to such a reputable standard is a testament to the compound’s superior quality, making it a formidable choice for critical applications in the demanding field of oil and gas extraction and production. | -35°C to 160°C (-30°F to 320°F)

|

| 460360-B

| General Purpose FKM 80A (Fluoroelastomer, Viton®)

| FKM (Fluoroelastomer) is an exceptional sealing material valued for its high-temperature resistance and compatibility with various chemicals. It operates efficiently within a temperature range of -26°C to 204°C (-15°F to 400°F), making it suitable for high-temperature environments and/or applications demanding chemical resistance. FKM seals are resistant to an array of substances including HFD-S and R fluids, mineral, vegetable, silicone, and biodegradable oils, hydrocarbons, alcohols, diesel, gasoline, fuels, ozone, oxygen, and air up to 200°C. However, they are not resistant to steam. Commonly used for both static and dynamic sealing applications, FKM is ideal for standard and special seals, wipers, O-rings, flange seals, and rotary seals, as well as for rubber energizers or preload elements in various sealing configurations. Its resilience in facing extreme conditions is why FKM is the preferred choice in industries that prioritize longevity and reliability, such as aerospace, automotive, and chemical processing. | -26°C to 204°C (-15°F to 400°F)

|

| 441360-B

| General Purpose FKM 90A (Fluoroelastomer, Viton®)

| FKM (Fluoroelastomer) is an exceptional sealing material valued for its high-temperature resistance and compatibility with various chemicals. It operates efficiently within a temperature range of -26°C to 204°C (-15°F to 400°F), making it suitable for high-temperature environments and/or applications demanding chemical resistance. FKM seals are resistant to an array of substances including HFD-S and R fluids, mineral, vegetable, silicone, and biodegradable oils, hydrocarbons, alcohols, diesel, gasoline, fuels, ozone, oxygen, and air up to 200°C. However, they are not resistant to steam. Commonly used for both static and dynamic sealing applications, FKM is ideal for standard and special seals, wipers, O-rings, flange seals, and rotary seals, as well as for rubber energizers or preload elements in various sealing configurations. Its resilience in facing extreme conditions is why FKM is the preferred choice in industries that prioritize longevity and reliability, such as aerospace, automotive, and chemical processing. | -26°C to 204°C (-15°F to 400°F)

|

| FKM80BRN-B

| Brown FKM 80A (Fluoroelastomer, Viton®)

| The FKM80BRN-B, a brown Fluorocarbon elastomer widely known by the trade names VITON® and FKM, is an advanced sealing material recognized for its formidable resistance to heat, hydraulic fluids, chemicals, and various organic compounds. It exhibits exceptional performance in temperatures ranging from -25°C to 210°C (-13°F to 410°F). FKM seals are resistant to an array of substances including HFD-S and R fluids, mineral, vegetable, silicone, and biodegradable oils, hydrocarbons, alcohols, diesel, gasoline, fuels, ozone, oxygen, and air up to 200°C. However, they are not resistant to steam. Commonly used for both static and dynamic sealing applications, FKM is ideal for standard and special seals, wipers, O-rings, flange seals, and rotary seals, as well as for rubber energizers or preload elements in various sealing configurations. Its resilience in facing extreme conditions is why FKM is the preferred choice in industries that prioritize longevity and reliability, such as aerospace, automotive, and chemical processing. | -25°C to 210°C (-13°F to 410°F),

|

| FKM90BRN-B

| Brown FKM 90A (Fluoroelastomer, Viton®)

| The FKM90BRN-B, a brown Fluorocarbon elastomer widely known by the trade names VITON® and FKM, is an advanced sealing material recognized for its formidable resistance to heat, hydraulic fluids, chemicals, and various organic compounds. It exhibits exceptional performance in temperatures ranging from -25°C to 210°C (-13°F to 410°F). FKM seals are resistant to an array of substances including HFD-S and R fluids, mineral, vegetable, silicone, and biodegradable oils, hydrocarbons, alcohols, diesel, gasoline, fuels, ozone, oxygen, and air up to 200°C. However, they are not resistant to steam. Commonly used for both static and dynamic sealing applications, FKM is ideal for standard and special seals, wipers, O-rings, flange seals, and rotary seals, as well as for rubber energizers or preload elements in various sealing configurations. Its resilience in facing extreme conditions is why FKM is the preferred choice in industries that prioritize longevity and reliability, such as aerospace, automotive, and chemical processing. | -25°C to 210°C (-13°F to 410°F),

|

You’ve made it this far, but we know there is still more to discuss. Click on the book a meeting button below to easily setup up a date and time to talk more about your project. You can also email us at info@kcseals.ca