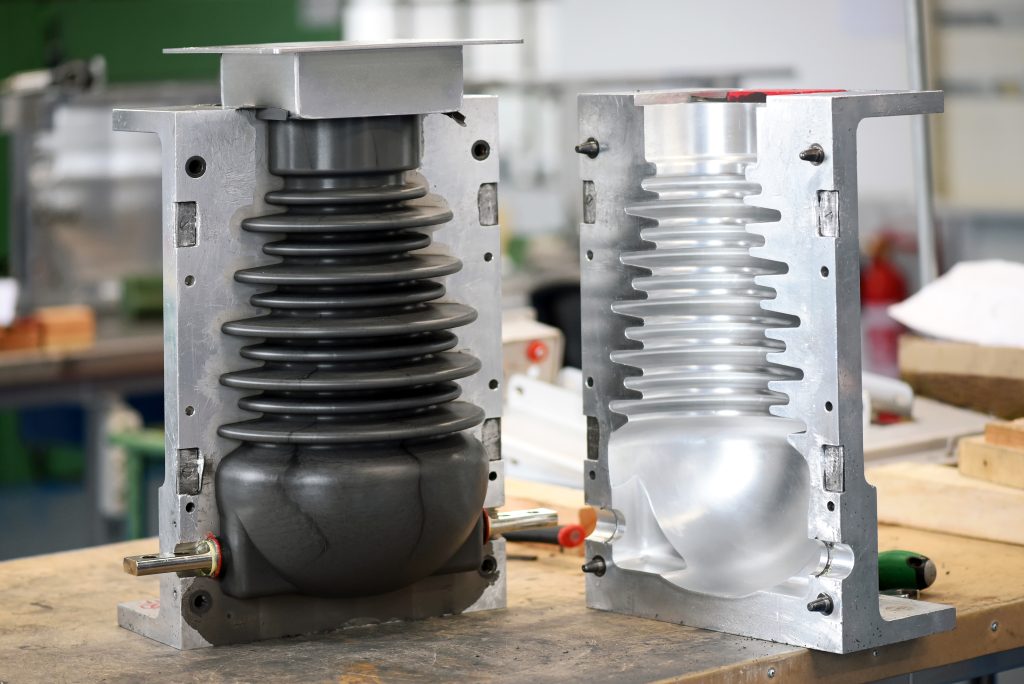

In-House mold making

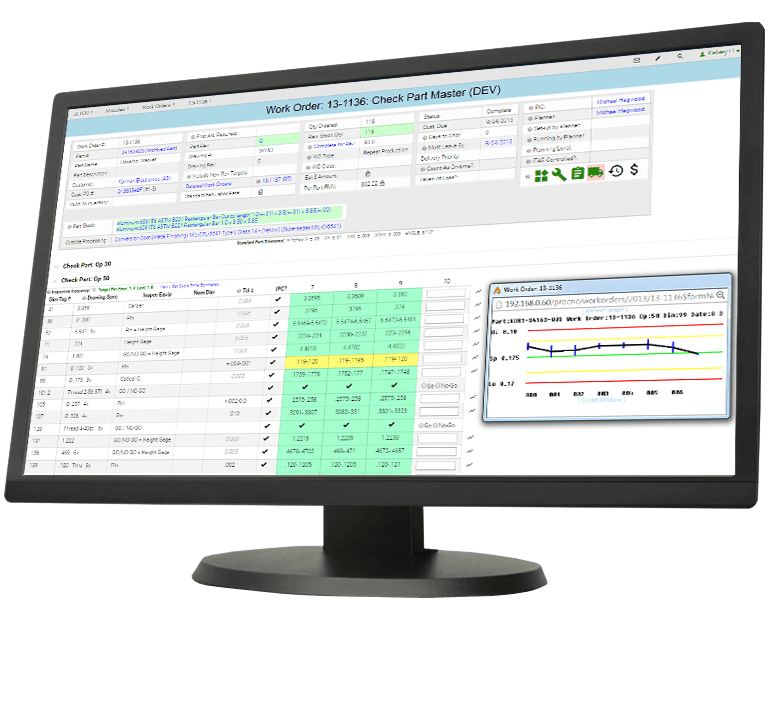

Setup fees can often hinder project progression, but at KC Seals, we eliminate this barrier with our in-house compression mold production. By handling everything internally, we not only reduce costs but also significantly speed up the process, ensuring your project moves forward swiftly. Additionally, keeping your intellectual property under one roof ensures maximum security and eliminates the need to rely on unfamiliar external machine shops. This streamlined approach saves you both time and money, making your decision to proceed easier and more efficient.