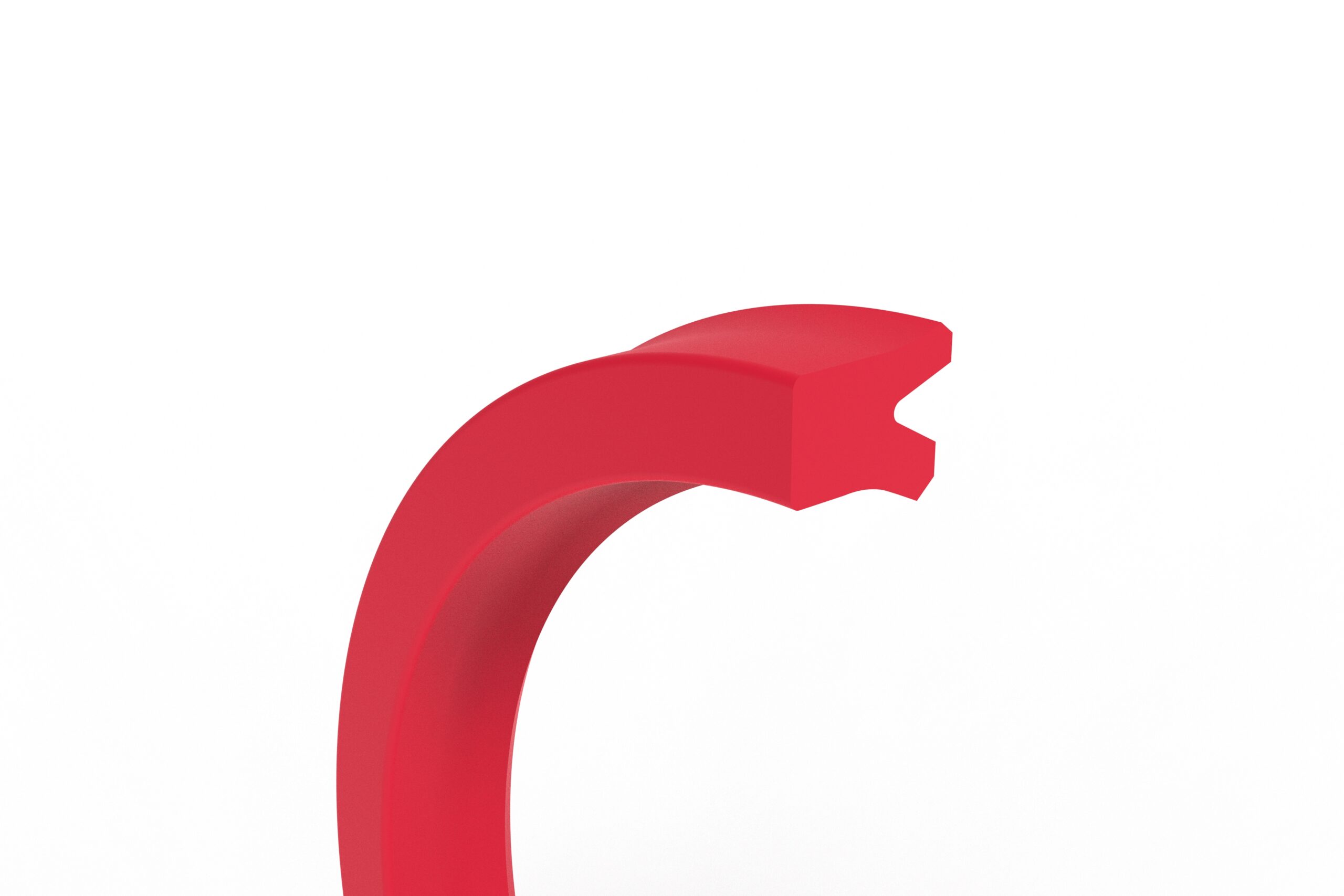

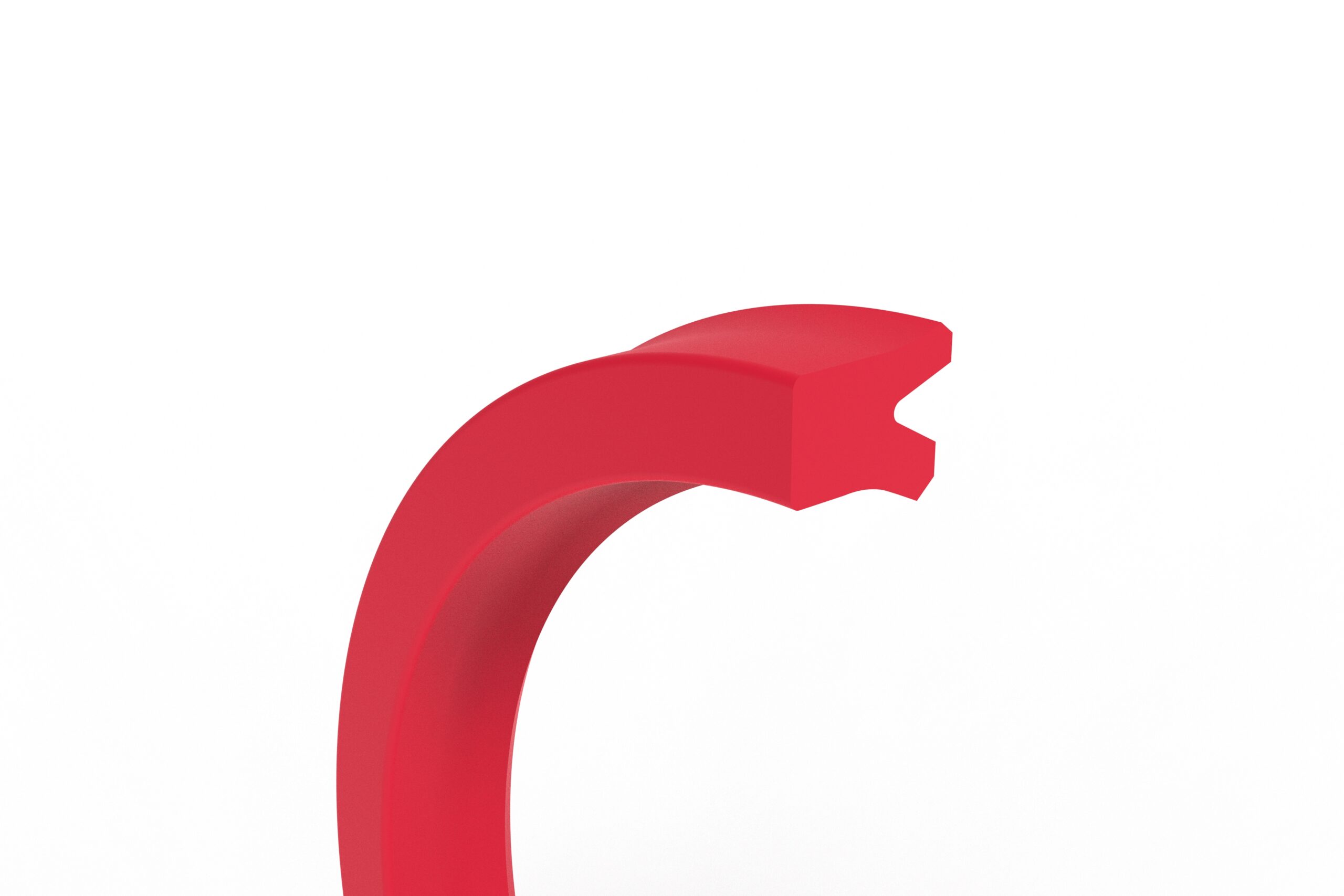

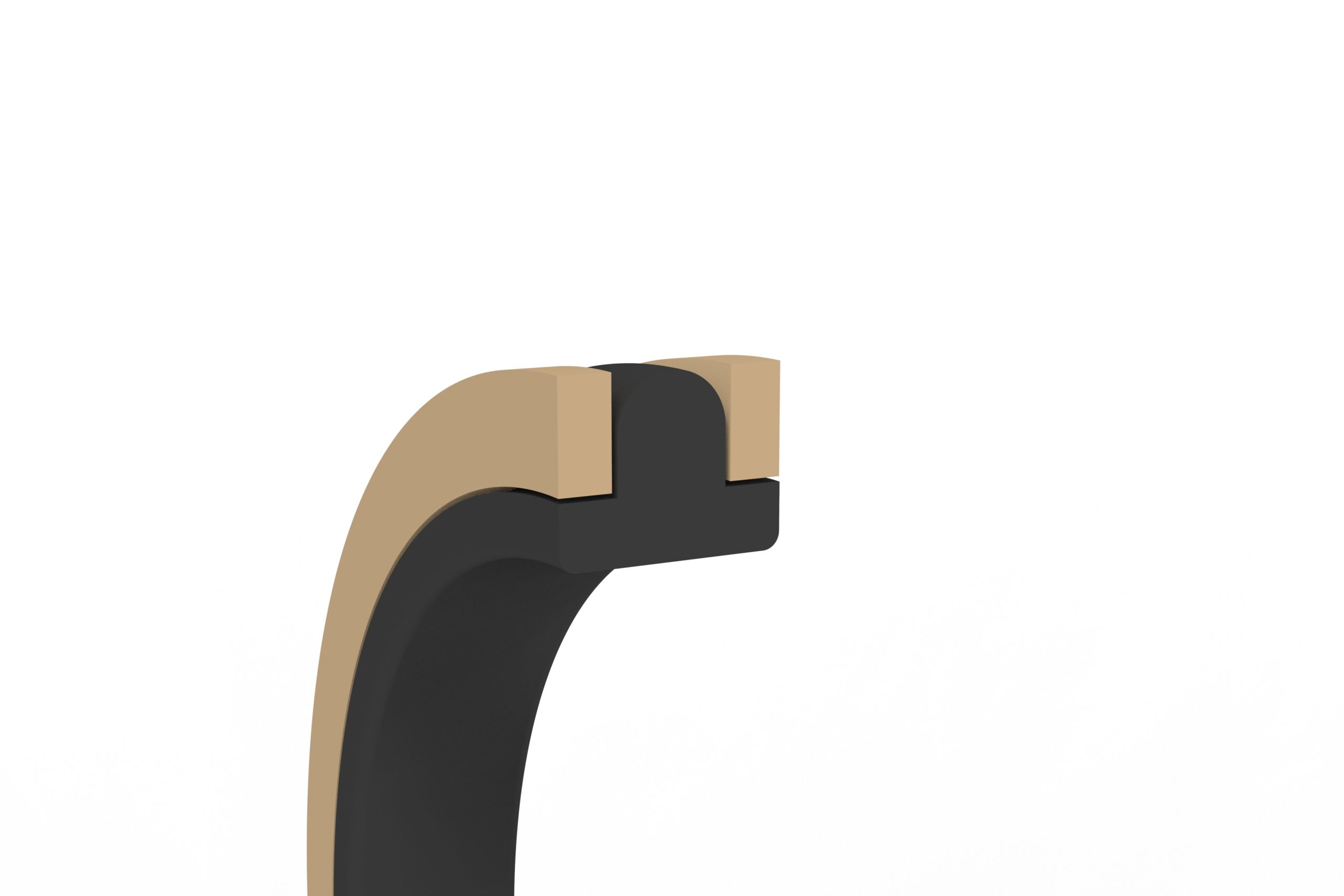

EnduraFlex EFS

Enhanced rod seal with exceptional wear resistance

- Pressure range: Maximum of 5,800 psi (40 MPa)

- Temperature Range: -50°C to +135°C | -58°F to +275°F

- Max Speed: Up to 1.65 feet per second (0.5 meters per second)

Piston seals are essential components in hydraulic and pneumatic cylinders, designed to create a reliable barrier between the piston and the cylinder bore. This separation is crucial as it prevents fluid leakage and ensures the smooth movement of the piston, which is fundamental for the efficient operation of the system. Piston seals are available in both single-acting and double-acting configurations, tailored to different pressure and motion requirements. Single-acting seals are optimized for applications where pressure is applied from one direction, whereas double-acting seals can handle pressure from both sides, making them suitable for bi-directional piston movements.

These seals come in various profiles such as U-cups, lip seals, and compact seals, each offering unique benefits. U-cup seals, with their U-shaped cross-section, provide a stable and flexible sealing lip that enhances the seal under pressure, making them ideal for a wide range of applications. Lip seals feature a flexible lip that ensures tight sealing against the cylinder wall, effectively preventing leaks and accommodating slight misalignments. Compact seals combine multiple sealing elements into a single unit, providing enhanced performance in a smaller footprint, which is particularly useful in space-constrained applications.

Material selection for piston seals is critical to their performance and durability. Thermoplastic polyurethane (TPU) offers high wear resistance and good low-temperature flexibility, making it suitable for various hydraulic and pneumatic applications. Polytetrafluoroethylene (PTFE) is prized for its outstanding chemical resistance, low friction, and high-temperature stability, ideal for aggressive media and high-temperature operations. Nitrile rubber (NBR) is commonly used for its excellent resistance to oils and fuels and its good performance in low temperatures. Fluorocarbon rubber (FKM), known for its high-temperature resistance and chemical stability, is suitable for challenging environments found in the automotive and aerospace industries.

Choosing the right piston seal involves considering operating conditions such as temperature, pressure, and media compatibility, ensuring the selected seal profile and material can meet the specific demands of the application

Piston seals are essential components in hydraulic and pneumatic cylinders, designed to create a reliable barrier between the piston and the cylinder bore. This separation is crucial as it prevents fluid leakage and ensures the smooth movement of the piston, which is fundamental for the efficient operation of the system. Piston seals are available in both single-acting and double-acting configurations, tailored to different pressure and motion requirements. Single-acting seals are optimized for applications where pressure is applied from one direction, whereas double-acting seals can handle pressure from both sides, making them suitable for bi-directional piston movements.

These seals come in various profiles such as U-cups, lip seals, and compact seals, each offering unique benefits. U-cup seals, with their U-shaped cross-section, provide a stable and flexible sealing lip that enhances the seal under pressure, making them ideal for a wide range of applications. Lip seals feature a flexible lip that ensures tight sealing against the cylinder wall, effectively preventing leaks and accommodating slight misalignments. Compact seals combine multiple sealing elements into a single unit, providing enhanced performance in a smaller footprint, which is particularly useful in space-constrained applications.

Material selection for piston seals is critical to their performance and durability. Thermoplastic polyurethane (TPU) offers high wear resistance and good low-temperature flexibility, making it suitable for various hydraulic and pneumatic applications. Polytetrafluoroethylene (PTFE) is prized for its outstanding chemical resistance, low friction, and high-temperature stability, ideal for aggressive media and high-temperature operations. Nitrile rubber (NBR) is commonly used for its excellent resistance to oils and fuels and its good performance in low temperatures. Fluorocarbon rubber (FKM), known for its high-temperature resistance and chemical stability, is suitable for challenging environments found in the automotive and aerospace industries.

Choosing the right piston seal involves considering operating conditions such as temperature, pressure, and media compatibility, ensuring the selected seal profile and material can meet the specific demands of the application

Enhanced rod seal with exceptional wear resistance

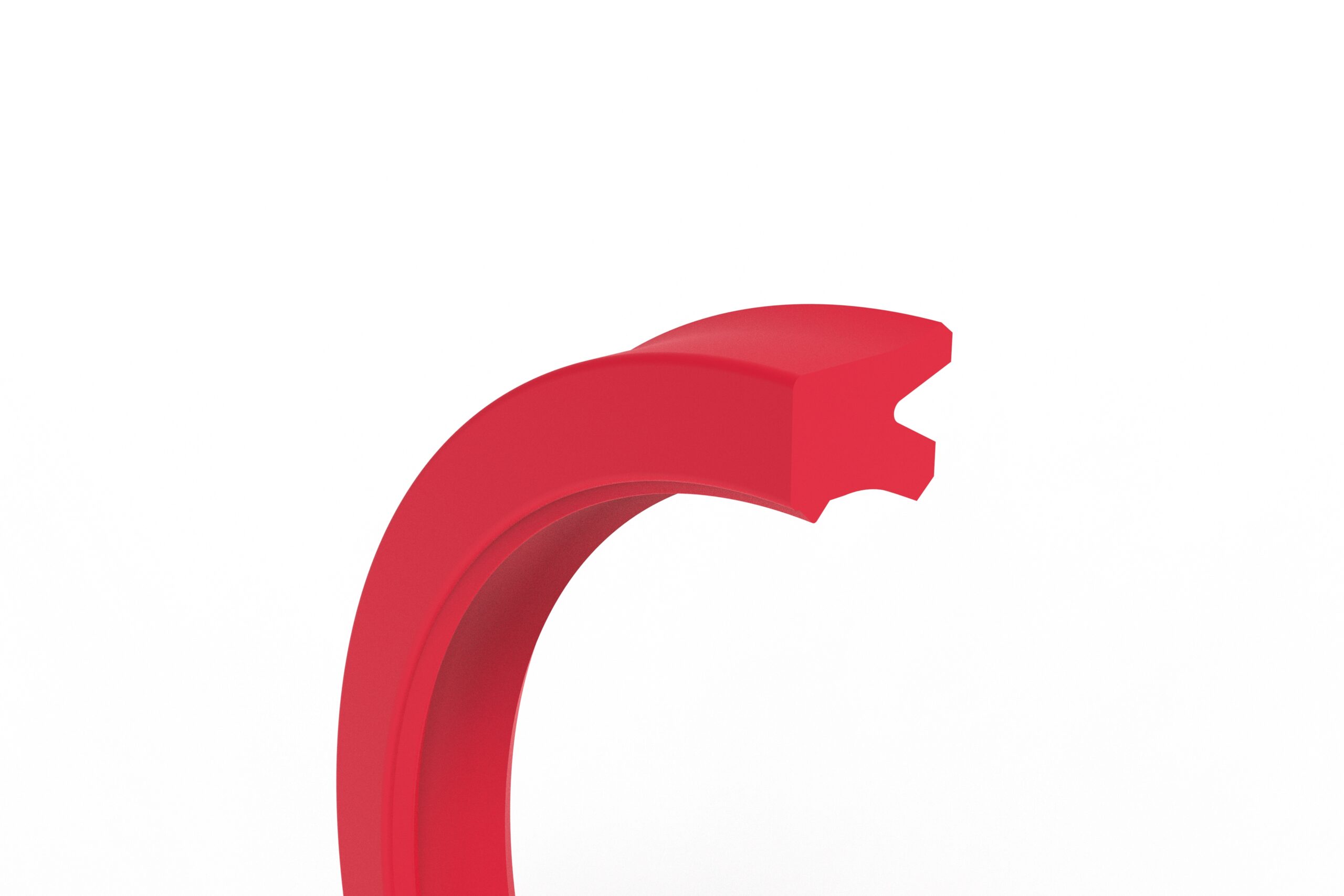

Exceptional rod seal with enhanced axial stability

Larger interference face for improved sealing efficiency

O-Ring Loaded U-Cups enhance low-pressure sealing

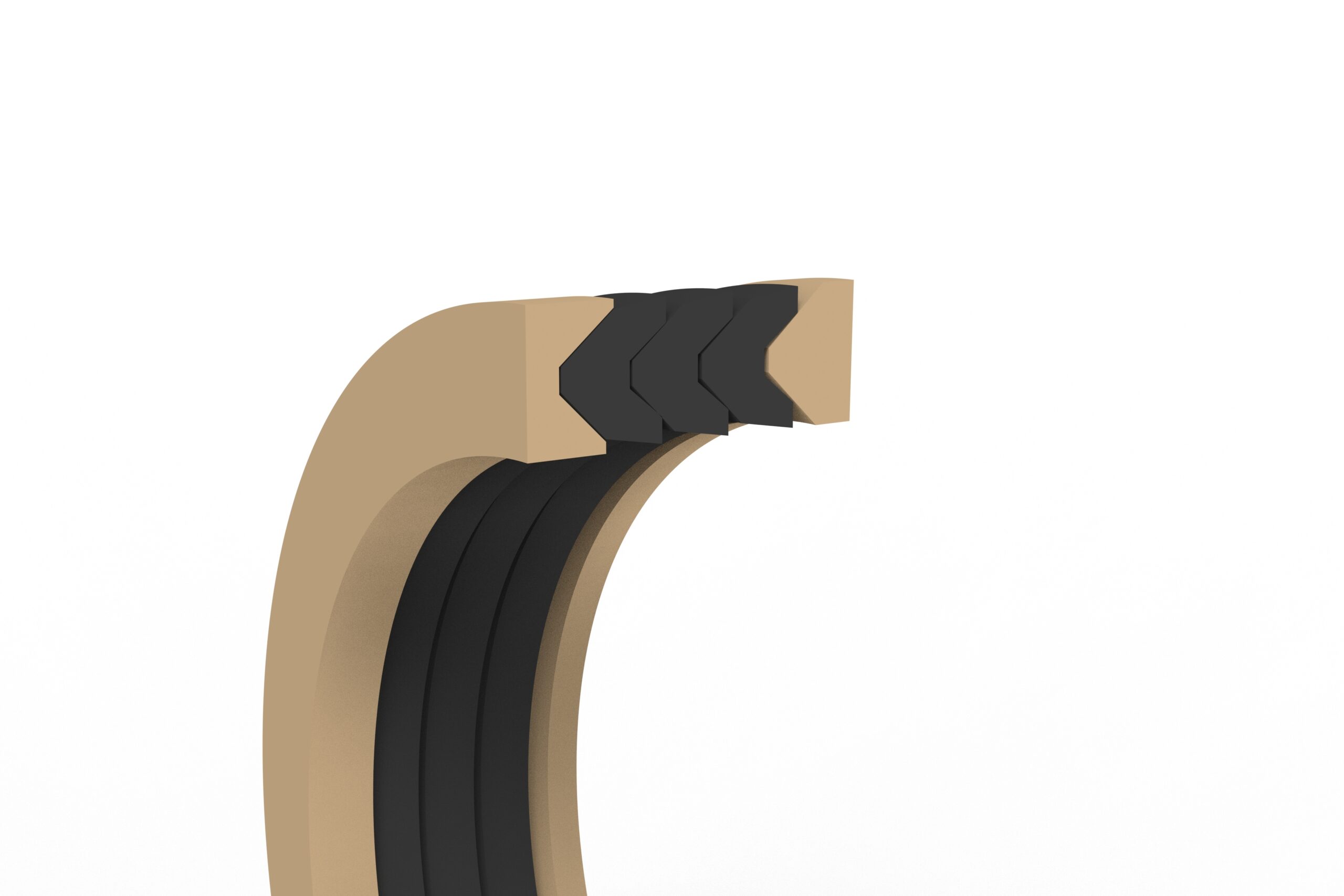

Versatile V-Seals for high-pressure hydraulic applications

One-piece high-pressure seal for dynamic applications

High-performance seal stack for HPHT applications

Superior O-ring alternative for high-pressure sealing

The Engi-Seal RC4 ensures low friction and long life

Durable, low wear, with multiple redundant seal lips

Rounded sealing lip for even stress distribution

Beveled sealing lip ensures optimal gas and vapor sealing

Optimized for superior sealing, and friction reduction at high-speeds

Optimized for superior sealing, and friction reduction at high-speeds

High-pressure piston seal with integrated guide rings

Durable, high-performance seal for mining equipment