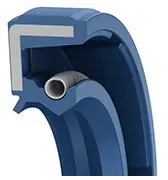

ASL Single Lip

Spring-loaded single-lip

- Pressure range: Maximum of 7 psi

- Temperature Range: -40 to 200°C | -40 to 392°F

- Max Speed: Up to 43 feet per second

KC Seals is renowned for its expertise in rotary seals, specifically spring-energized seals and radial shaft seals, which are critical components in various engineering applications. These seals are designed to withstand demanding operational conditions, ensuring optimal performance and longevity.

Spring-energized seals, such as the EngiSeal® from KC Seals, are engineered to provide robust sealing solutions in environments where traditional elastomeric seals might fail. These seals utilize a variety of jacket profiles, spring types, and materials, including PTFE and other high-performance polymers. The springs, made from corrosion-resistant metal alloys like stainless steel and Elgiloy®, maintain constant force on the sealing lips, ensuring a gas-tight seal even under fluctuating pressures and temperatures. This makes them ideal for applications requiring low friction, chemical resistance, and high-temperature endurance. The spring’s resilience also compensates for wear and thermal cycling, maintaining effective sealing over extended periods.

Radial shaft seals are essential components that sit between rotating and stationary elements or between parts in relative motion. They consist of two primary components: a cylindrical outer casing that fits tightly against the housing bore to ensure a static seal, and a sealing lip that dynamically and statically seals against the shaft by exerting a specific radial force on its surface.

The effectiveness of radial shaft seals is enhanced by materials with high chemical and thermal resistance, superior pump rates, and special coatings that compensate for any surface imperfections in the housing bore. These seals are designed to be robust and comply with both national and international standards.

Typical applications of radial shaft seals include gearboxes, hydraulic pumps, axles, power steering columns, speed reducers, and transmissions. Their versatile design ensures reliable performance in various industrial and automotive systems, maintaining the integrity and efficiency of the machinery.

KC Seals is renowned for its expertise in rotary seals, specifically spring-energized seals and radial shaft seals, which are critical components in various engineering applications. These seals are designed to withstand demanding operational conditions, ensuring optimal performance and longevity.

Spring-energized seals, such as the EngiSeal® from KC Seals, are engineered to provide robust sealing solutions in environments where traditional elastomeric seals might fail. These seals utilize a variety of jacket profiles, spring types, and materials, including PTFE and other high-performance polymers. The springs, made from corrosion-resistant metal alloys like stainless steel and Elgiloy®, maintain constant force on the sealing lips, ensuring a gas-tight seal even under fluctuating pressures and temperatures. This makes them ideal for applications requiring low friction, chemical resistance, and high-temperature endurance. The spring’s resilience also compensates for wear and thermal cycling, maintaining effective sealing over extended periods.

Radial shaft seals are essential components that sit between rotating and stationary elements or between parts in relative motion. They consist of two primary components: a cylindrical outer casing that fits tightly against the housing bore to ensure a static seal, and a sealing lip that dynamically and statically seals against the shaft by exerting a specific radial force on its surface.

The effectiveness of radial shaft seals is enhanced by materials with high chemical and thermal resistance, superior pump rates, and special coatings that compensate for any surface imperfections in the housing bore. These seals are designed to be robust and comply with both national and international standards.

Typical applications of radial shaft seals include gearboxes, hydraulic pumps, axles, power steering columns, speed reducers, and transmissions. Their versatile design ensures reliable performance in various industrial and automotive systems, maintaining the integrity and efficiency of the machinery.

Spring-loaded single-lip

Metal rubber encased double lip

Single metal encased single lip

Single metal encased double lip

Single metal encased no lip

Double metal encased double lip

Double metal encased single lip

High pressure radial shaft seal

O-Ring stabilized high performance rotary seal

Locks in place, reduces friction effectively.

Versatile sealing for dynamic rotary applications

Versatile sealing for dynamic rotary applications