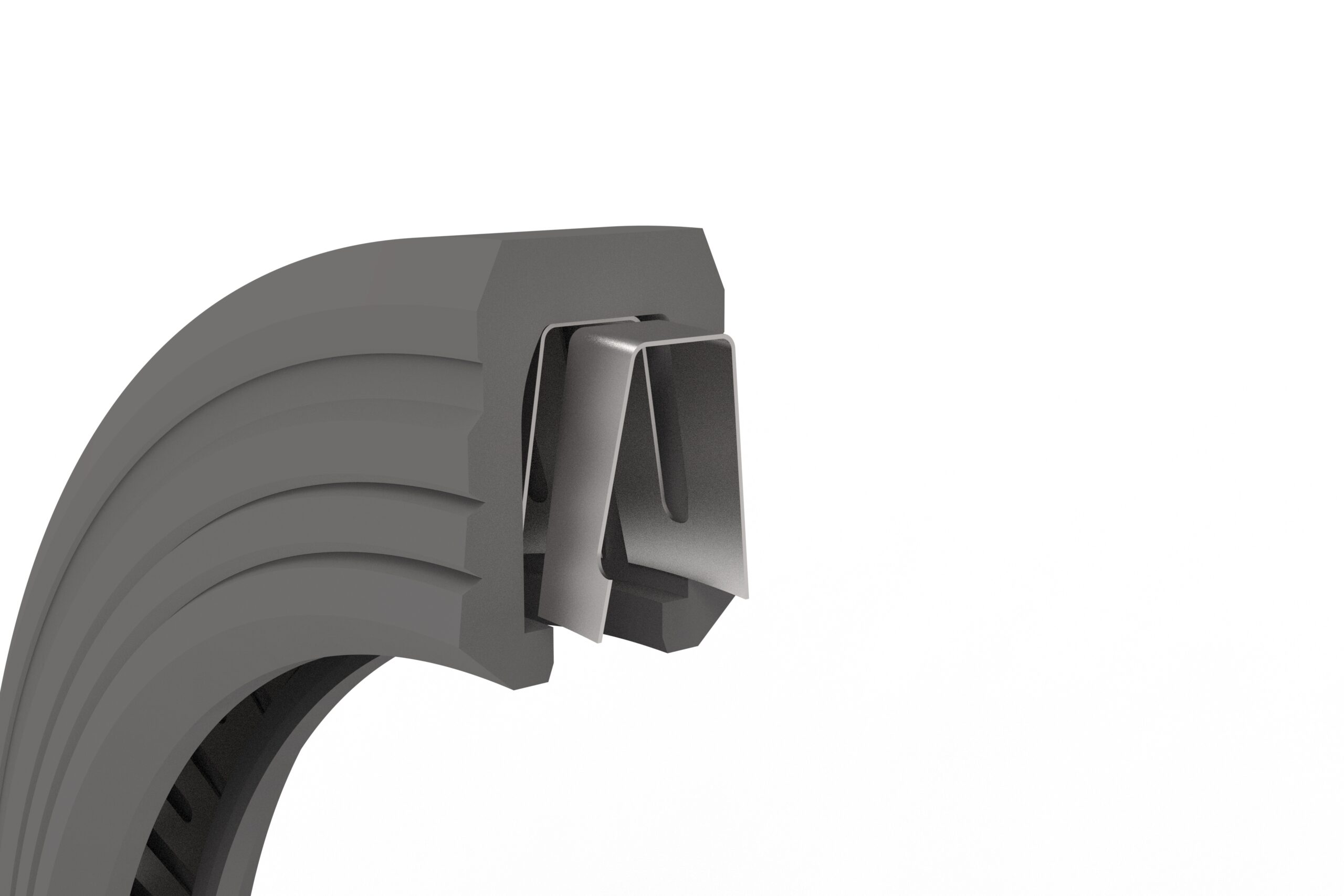

Engi-Seal Face RV6

Durable, low wear, with multiple redundant seal lips

- Pressure range: Maximum of 3,000 psi

- Temperature Range: -270°C to +260°C | -450°F to +500°F

Durability and Reliability in critical applications

Spring Energized Face Seals are advanced sealing solutions designed to handle some of the most demanding service conditions. These seals are essentially spring-loaded u-cups, which integrate high-performance polymer seal jackets with cutting-edge spring technology. The innovative combination of these materials allows for exceptional performance in environments characterized by high temperatures, exposure to harsh chemicals, and requirements for low friction.

The seal jackets, made from high-grade polymers, offer excellent resistance to wear, chemicals, and temperature extremes. The springs, acting as jacket energizers, ensure consistent sealing force, even under varying pressures and temperatures. This synergy between the seal jacket and the spring results in reliable sealing performance across a wide range of applications.

Spring Energized Face Seals are versatile and can be designed to fit all standard hardware glands. They can also be customized to suit non-standard housings, providing flexibility in design and application. Additionally, the sealing profile geometries of these seals can be modified to enhance sealing performance, catering to specific operational requirements.

These seals are ideal for applications where traditional seals may fail, offering solutions for industries such as aerospace, oil and gas, pharmaceuticals, and chemical processing. Their ability to maintain integrity under extreme conditions makes them a preferred choice for ensuring long-lasting and effective sealing in critical environments.

You’ve made it this far, but we know there is still more to discuss. Click on the book a meeting button below to easily setup up a date and time to talk more about your project. You can also email us at info@kcseals.ca

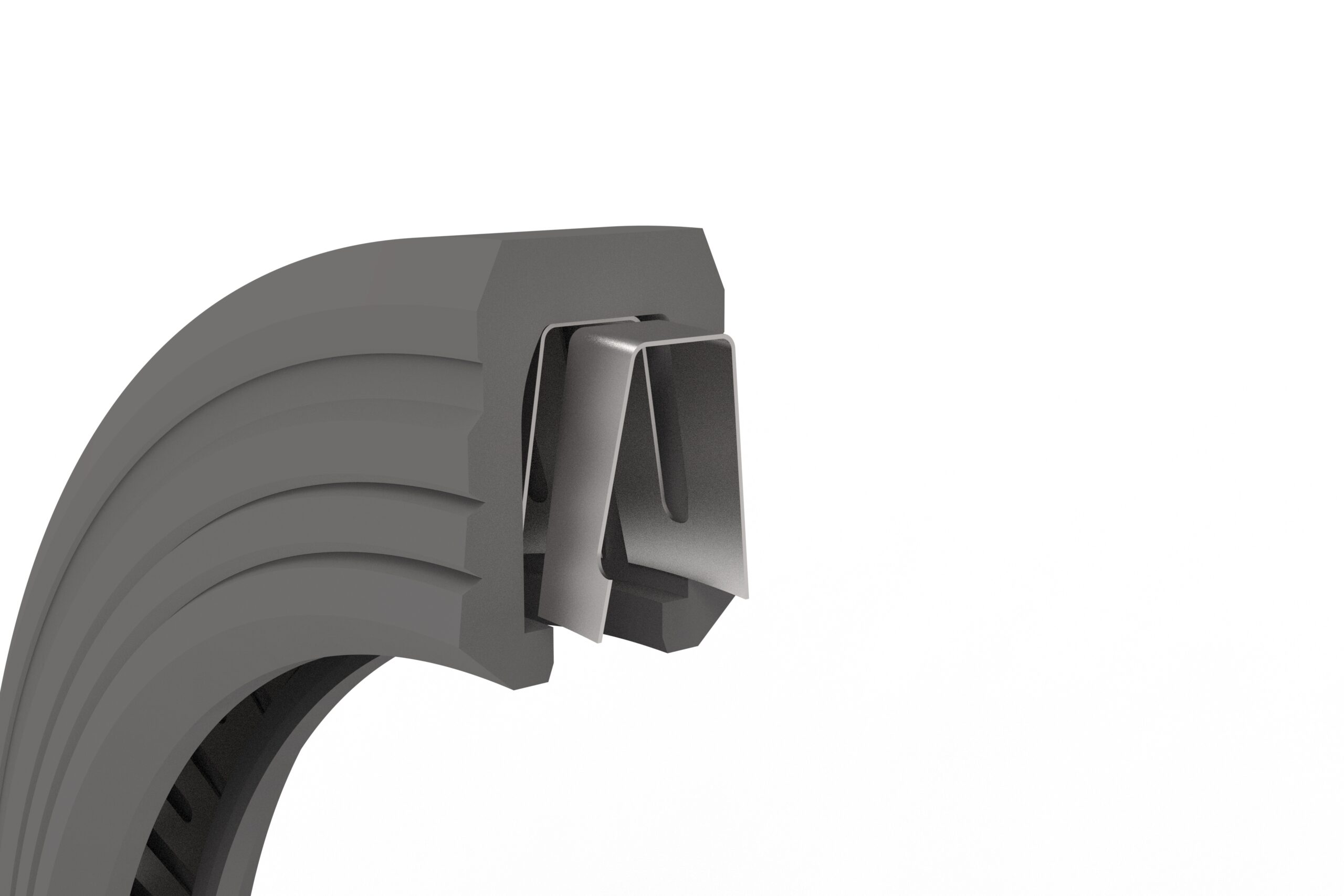

Spring Energized Face Seals are advanced sealing solutions designed to handle some of the most demanding service conditions. These seals are essentially spring-loaded u-cups, which integrate high-performance polymer seal jackets with cutting-edge spring technology. The innovative combination of these materials allows for exceptional performance in environments characterized by high temperatures, exposure to harsh chemicals, and requirements for low friction.

The seal jackets, made from high-grade polymers, offer excellent resistance to wear, chemicals, and temperature extremes. The springs, acting as jacket energizers, ensure consistent sealing force, even under varying pressures and temperatures. This synergy between the seal jacket and the spring results in reliable sealing performance across a wide range of applications.

Spring Energized Face Seals are versatile and can be designed to fit all standard hardware glands. They can also be customized to suit non-standard housings, providing flexibility in design and application. Additionally, the sealing profile geometries of these seals can be modified to enhance sealing performance, catering to specific operational requirements.

These seals are ideal for applications where traditional seals may fail, offering solutions for industries such as aerospace, oil and gas, pharmaceuticals, and chemical processing. Their ability to maintain integrity under extreme conditions makes them a preferred choice for ensuring long-lasting and effective sealing in critical environments.

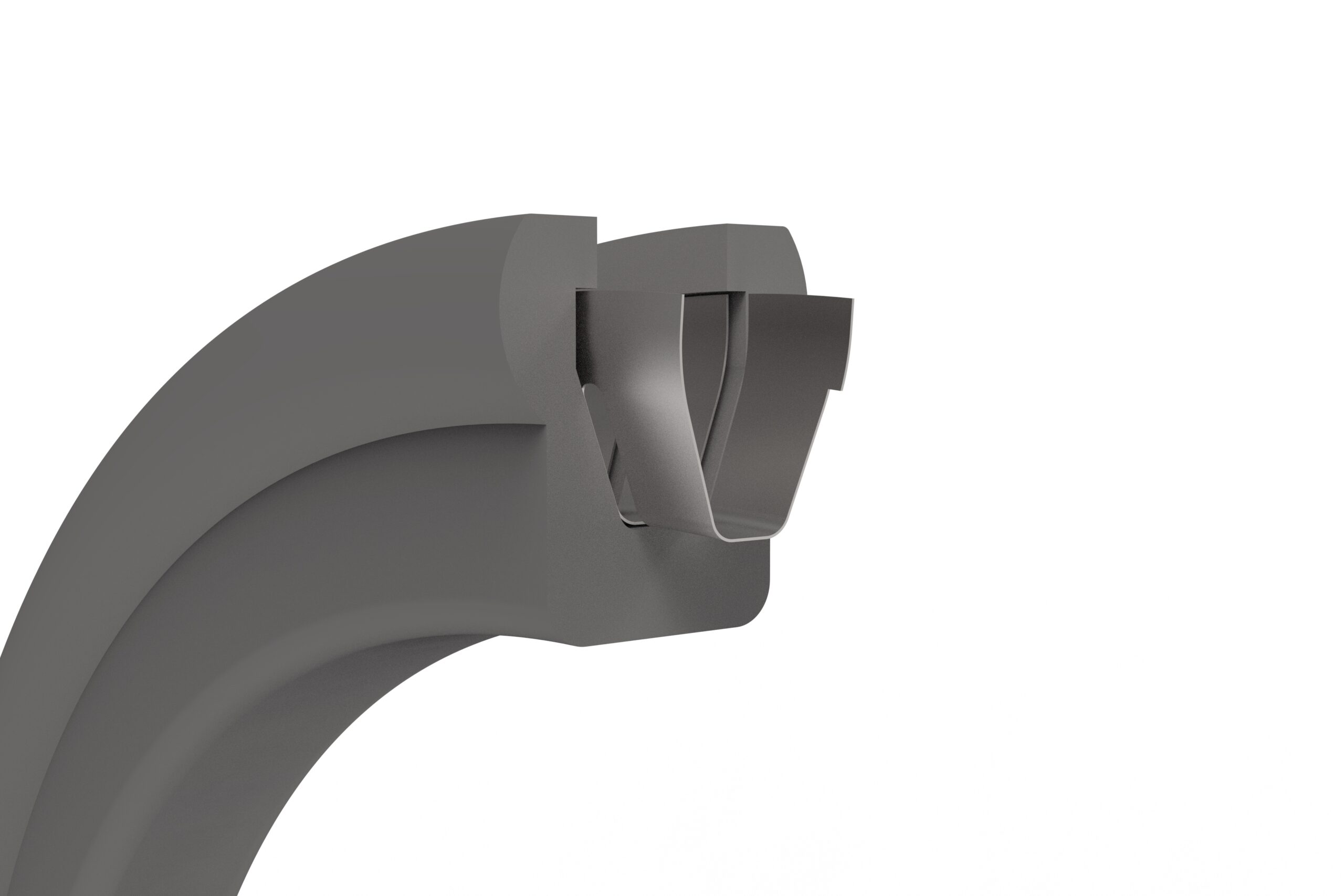

Durable, low wear, with multiple redundant seal lips

Rounded sealing lip for even stress distribution

Beveled sealing lip ensures optimal gas and vapor sealing

You’ve made it this far, but we know there is still more to discuss. Click on the book a meeting button below to easily setup up a date and time to talk more about your project. You can also email us at info@kcseals.ca