The simple 3-piece sealing solution for high pressure applications

The simple 3-piece sealing solution for high pressure applications

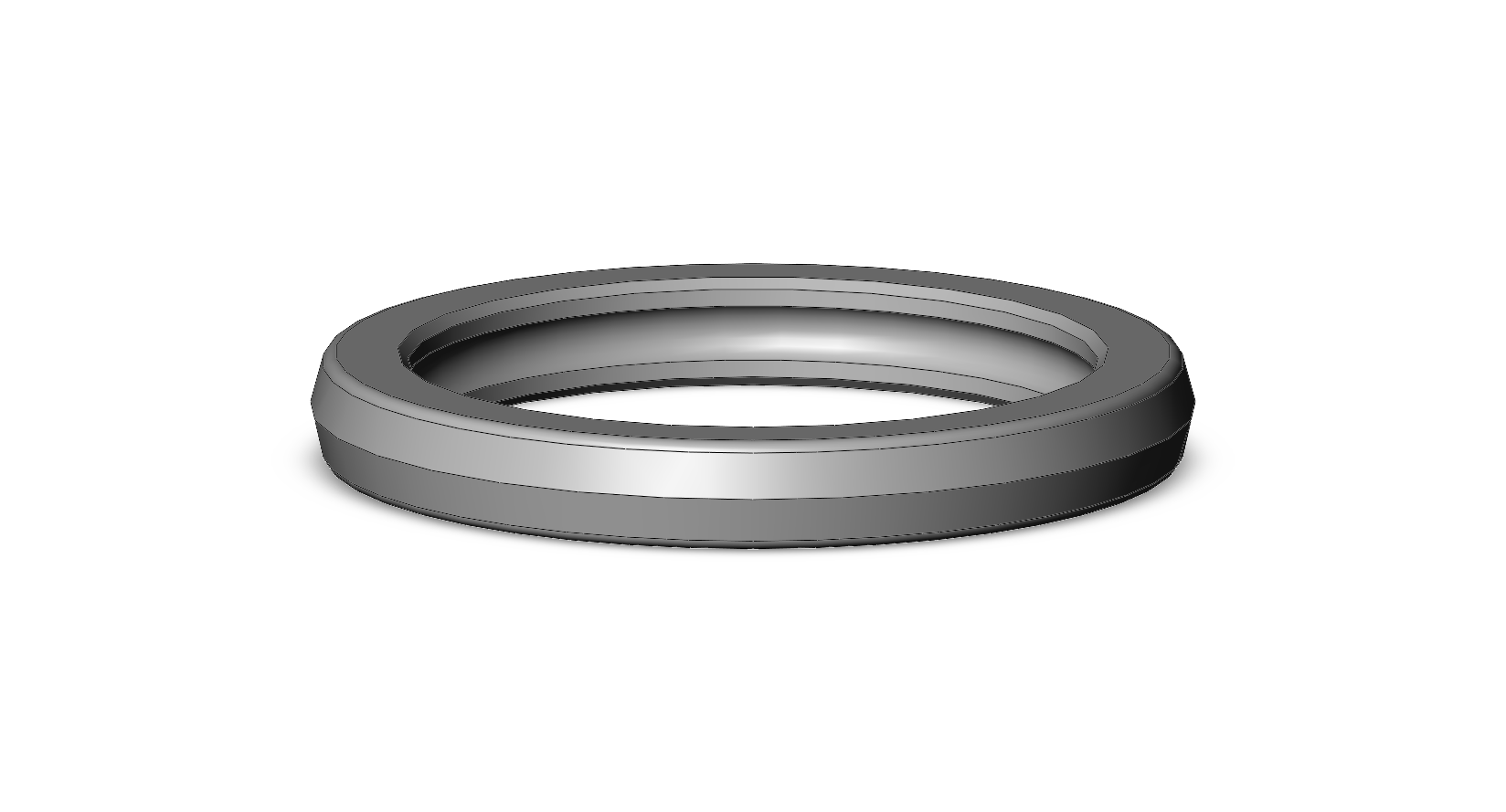

T-seals are a specialized type of seal utilized in various industrial and aerospace applications, designed to supplant O-rings in dynamic fluid power scenarios. These seals tackle the common reliability issues that O-rings encounter, such as extrusion through gaps and instability that leads to spiral failure. T-seals comprise an elastomeric seal element with a distinctive T-shaped cross-section, alongside back-up rings that inhibit extrusion and augment performance.

The design of T-seals enables them to retain the compact dimensions and pressure sealing capabilities of O-rings while eliminating their significant drawbacks. The elastomeric seal element features a body that provides the necessary squeeze or interference seal against dynamic surface loads and a flange that enhances the static seal against the groove walls. This configuration ensures the T-seal maintains a robust seal across all pressures and temperatures. The square or rectangular configuration of the T-seal assembly, with its back-up rings, prevents spiral failure, a common issue with O-rings.

Back-up rings are integral to the effectiveness of T-seals, positioned on the outside diameters of piston T-seals and the inside diameters of rod T-seals. They quickly respond to pressure changes, maintaining zero extrusion gaps despite the varying conditions encountered during operation. These back-up rings can be fabricated from materials offering high extrusion resistance without sacrificing quick response to gap changes.

In essence, T-seals offer a versatile and dependable sealing solution, improving upon the traditional O-ring design by addressing its limitations. Whether for aerospace or industrial applications, these seals provide enhanced durability and reliability, supporting a wide array of dynamic fluid power applications.

• Excellent stability in the groove

• Profile design prevents spiraling in the groove during installation and while in service

• 3-piece design with split back-up rings enables easy installation.

• Excellent temperature variability with multiple material selections

• Excellent bi-directional seal

• Fits in all AS568 O-Ring grooves

Operating Pressure: 20,000 psi for static applications. 15,000 psi for dynamic applications.

Speed: 3.3 ft/s or higher for non-continuous or intermittent use.

Temperature range: -45 °C to +232 °C depending on the elastomer.

| MATERIAL | DESCRIPTION | TEMPERATURE RANGE | DO NOT USE IN |

| Standard Grade Viton® | FKM type A commercial grade compound. Off the shelf, low cost, and highly accessible Viton® compound. | -20°C to +205°C, -4°F to 400°F | Strong Polar Solvents, Methyl Ethyl Ketone, Methyl Isobutyl Ketone, Ethylene Diamine, Acetone, phosphate ester hydraulic fluids, Ammonia, Concentrated Sulfuric Acid, Concentrated Nitric Acid, Chloroform, Methanol, Ketones and Ester. |

| Aflas® | Aflas® is becoming more and more of a staple in the oil and gas sector. Mostly because of its excellent steam; in fact, Alfas® was unaffected by extended exposure to 200°C in steam. Alfas® also boasts: Resistant to acids and bases, amines and H2S resistance, Ozone resistance and is resistant to highly reactive organic and inorganic chemicals. | -4 to 232°C 25°F to 450°F | Aromatic Fuels, Ketones, Chlorinated Hydro Carbons, Esters, Strong polar solvents, aromatic hydrocarbons, concentrated strong acids at high temperatures, ammonia gas under pressure and temperauture, Halogenated compounds, and Nitro hydrocarbons. |

| Standard Grade HNBR | A general applications compound HNBR. HSN provides good chemical resistance to crude oil, lubricating agents and oil additives with superior resistance to carbon dioxide, water, drilling mud and amine corrosion inhibitors. HSN is off the shelf, low cost, and highly accessible HNBR compound. | -40°C to 160°C -40°F to 325°F | Strong polar solvents, concentrated oxidizing acids, chlorinated hydrocarbons, aromatic aolvents, esters and ketones, strong bases, aldehydes, phosphate ester hydraulic fluids, and ammonia gas. |

| Standard Grade NBR (BUNA) | Low-cost general-purpose compound. Even with its low cost, Nitrile still offers good resistance to compression set and tear/abrasion. Nitrile is resistant to many petroleum oils/greases, hydraulic fluids, alcohol, ambient water, silicone greases, Diester base lubricants and ethylene-glycol based fluids. | -35°C to +120°C -30°F to +250°F | Aromatic Fuels, Oxygenated automotive fuels, Strong acids and Alkalis, chlorinated solvents, petroleum oils and fuels at high temp, hydraulic fluids, atmospheric weathering, Vegetable and animal fats and oils. |

| MATERIAL | DESCRIPTION | TEMPERATURE RANGE |

| Unfilled PEEK | PEEK (Polyether Ether Ketone) back-up rings represent an advanced class of polymer solutions for extreme application conditions. Renowned for its mechanical strength, thermal stability, and chemical resistance, PEEK is used in environments where traditional materials fall short. | -70°C to +250°C (-158°F to +482°F) |

| PTFE | PTFE back-up rings are characterized by their exceptional resistance to chemicals, including most acids, bases, and solvents, making them suitable for a wide range of industries, including aerospace, automotive, and chemical processing. They exhibit minimal friction and are non-sticky, contributing to their effectiveness in applications requiring low frictional resistance. | -200°C to +260°C (-328°F to +500°F) |

| Nylon | Nylon is often selected as a material for backup rings due to its excellent mechanical properties, including high strength, stiffness, and good resistance to wear and abrasion. Additionally, the material’s low moisture absorption rate helps to minimize swelling and ensures consistent sealing effectiveness over time. Nylon backup rings are commonly utilized in hydraulic and pneumatic systems, where they enhance the overall durability and efficiency of the sealing arrangement. | -40°C to 100°C (-40°F to 212°F) |

You’ve made it this far, but we know there is still more to discuss. Click on the book a meeting button below and we can discuss over a phone or video call. You can also email us at info@kcseals.ca.