In the world of mechanical systems, it’s often the seemingly minor and cost-effective components that can have the most significant impacts. The loss of the Space Shuttle Challenger on January 28, 1986, tragically underscored this reality. The failure of an O-ring, led to one of the most catastrophic accidents in the history of space exploration. This incident highlights the crucial importance of O-rings and serves as a powerful reminder of their role in maintaining the integrity of mechanical systems.

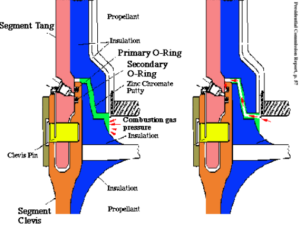

The official investigation into the Challenger disaster concluded that the loss of the shuttle was caused by a failure in the joint between the two lower segments of the right Solid Rocket Motor. The specific failure was the destruction of the seals, primarily the O-rings, which were intended to prevent hot gases from leaking through the joint during the rocket motor’s propellant burn. The failure of these small components allowed hot gases to escape, leading to the structural breakup of the shuttle.

Figure 1.1: The joints where the segments are joined together at KSC are known as field joints

(Source: Online Ethics Center for engineering and science)

The Challenger disaster was not just a result of a technical failure but also of a series of managerial and decision-making errors. Several factors contributed to the O-ring failure:

To prevent such a disaster, several actions should have been taken:

The humble O-ring is a perfect example of how often the least thought of and most likely one of the cheapest components can play critical roles in complex systems. The Challenger disaster is a sobering reminder of the potential consequences when these components fail. As we continue to innovate and develop new technologies, we must remember the lessons of the past and ensure that every part of our systems, no matter how small, or inexpensive, is given the attention it deserves. By doing so, we can prevent future tragedies and ensure the safety and reliability of our mechanical systems.

The next time you encounter an O-ring, remember that its proper function is vital to the success and safety of the entire system it serves.

Heimann, C.L., 1993. Understanding the Challenger disaster: Organizational structure and the design of reliable systems. American Political Science Review, 87(2), pp.421-435.