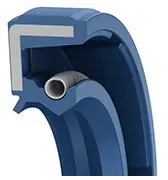

This product features a tension spring, a rubberized outer jacket, and a protective lip, along with a shortened sealing lip. The sealing materials used are FKM and NBR, with a reinforcement sheet made from unalloyed steel (DIN EN 10027-1) and a tension spring made from spring steel (DIN EN 10270-1).

Designed for dynamic sealing of a rotating shaft at high pressures, regardless of the direction of rotation, this product is self-retaining and ensures a good static seal between the sealing lip and the shaft when stationary. The rubberized outer jacket guarantees a tight fit and seal to the housing bore, while the protective lip prevents dirt accumulation from outside. The shortened sealing lip allows for higher operating pressure. However, increased friction can lead to a rise in temperature.

This product offers a very good static sealing effect with low-viscosity or gaseous media and compensates for thermal expansion, making it ideal for use in light metal housings. It provides excellent sealing with greater roughness and in split housings. The product boasts high chemical resistance, no stick-slip effect, superior quality, and the highest functional reliability. It has the longest service life, a compact design, and requires no support ring.

Suitable for pressurized units such as hydraulic pumps, motors, and hydrodynamic couplings, this product meets the highest standards of performance.

NBR:

FKM:

| Specification | Details |

| Pressure Capacity | Maximum of 145 psi. |

| Operational Speed | 43 ft/s |

| Temperature Range | -40 to 200°C | -40 to 392°F |

| Material | Description | Temperature Range |

| NBR | NBR (Nitrile Butadiene Rubber) is a highly valued sealing material due to its excellent resistance to oils, fuels, and other chemicals, making it an ideal choice for applications in the automotive and aerospace industries. With a temperature operating range, NBR provides versatility under varied environmental conditions. Very cost effective option. | -40°C to 120°C -40°F to 248°F |

| FKM | FKM (Fluoroelastomer) is highly regarded in the sealing industry for its exceptional resistance to high temperatures, chemicals, and aging, making it indispensable in aerospace, automotive, and chemical processing sectors. This material thrives across a wide temperature range, enabling its use in extreme conditions where other materials would fail. FKM’s remarkable compatibility with a wide variety of chemicals, including oil, fuel, and solvents, along with its ability to withstand harsh environmental factors, ensures its preference for high-performance seals, O-rings, and gaskets. Its robustness and longevity under aggressive conditions underscore FKM’s value as a premier choice for demanding sealing applications. | -20°C to 200°C -4°F to 392°F |

For comprehensive support on product sizing, housing details or to explore potential solutions tailored to your application, we invite you to book a meeting with us