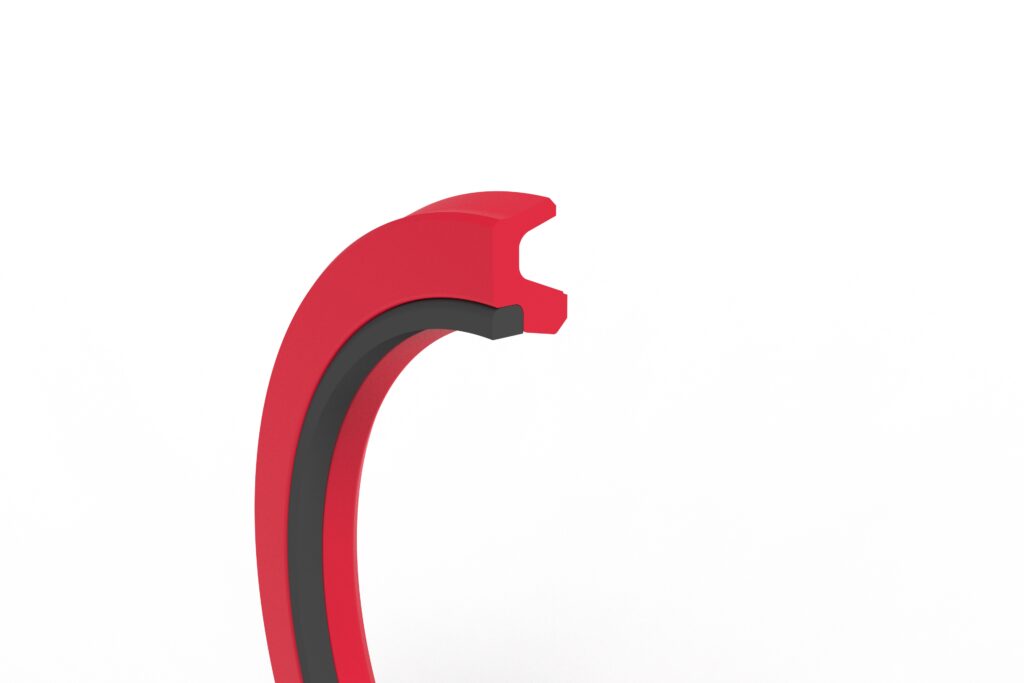

HP Buffer seals are polyurethane U-cup buffer seals featuring a polyurethane sealing ring with a polyamide (PA/Nylon) anti-extrusion ring. The flexible external static sealing lip and front face notches ensure that pressure can return to the system side of the buffer, preventing pressure build-up between the rod and buffer seals. These designs are ideal for extreme pressure peaks and heavy-duty applications up to 10,000 psi (70 MPa). Available in both metric and inch sizes, certain metric sizes comply with ISO 7425-2:1989 seal housing standards.

| Specification | Details |

| Pressure Capacity | Maximum of 10,000 psi (70 MPa) |

| Operational Speed | Varies depending on materials |

| Temperature Range | -200°C to +260°C | -328°F to 500°F |

| Material | Description | Temperature Range |

| PU100HT-95 | The PU100HT-95, a vibrant orange high-temperature resistant polyurethane, excels in extreme conditions with its superior hydrolysis and thermal aging resistance. It is ideal for sealing applications in the oil and gas industry, offering excellent performance under high pressure and against rapid gas decompression (RGD). Successfully passing rigorous RGD tests, it proves to be a reliable choice for challenging environments. | -30°C to 135°C -22°F to 275°F |

| PU300-57D | The PU300-57D is a hydrolysis-resistant cast polyurethane, engineered for dynamic sealing elements in applications requiring high performance under variable pressures up to 8700 psi (600 bar). With a hardness of 57 Shore D and notable chemical resistance and is designed to excel in conditions of poor lubrication or on rough and worn surfaces, makes it ideal for hydraulics, mining, and press machinery, as well as applications in contact with food substances. | 30°C to 125°C -22°F to 257°F |

| PU100LT-95 | The PU100H-95 is a hydrolysis-resistant, MDI-based cast polyurethane, renowned for its performance in low-temperature environments. This light blue material excels in hydraulic applications, excellent extrusion resistance, and robust chemical resistance against a variety of media, including water, mineral oils, and various hydraulic fluids. Its versatility makes it suitable for a wide range of sealing applications, from U-seals and wipers to packings and oil seals, particularly in settings demanding high durability and resistance to harsh conditions, while also being compliant with food contact regulations. | -50°C to 105°C -58°F to 221°F |

| PU100GP-93A | The PU100-93A, a cast polyurethane material, combines MDI, Polycarbonate Polyol, and specific additives to provide outstanding hydrolysis. This material boasts excellent chemical resistance and is suitable for both dynamic and static sealing applications in hydraulic systems, mining, and waterpower applications. Its advanced design ensures reduced friction and wear, making it ideal for use in U-seals, wipers, and packings, where high sealing efficiency and low maintenance are paramount. | -30°C to 125°C -22°F to 257°F |

| Material | Description | Temperature Range |

| Nylon 66 | Nylon 66 is a synthetic polymer known for its high mechanical strength, durability, and excellent thermal stability. It is resistant to oils, solvents, and chemicals, making it ideal for automotive, industrial, and consumer applications. It maintains its properties at elevated temperatures and is used in a variety of demanding applications such as gears, bearings, textiles, and engineering plastics. The production process involves polycondensation of hexamethylenediamine and adipic acid. While energy-intensive, it is recyclable. | -40°C to 150°C (-40°F to 302°F) |

For comprehensive support on housing details or to explore potential solutions tailored to your application, we invite you to book a meeting with us