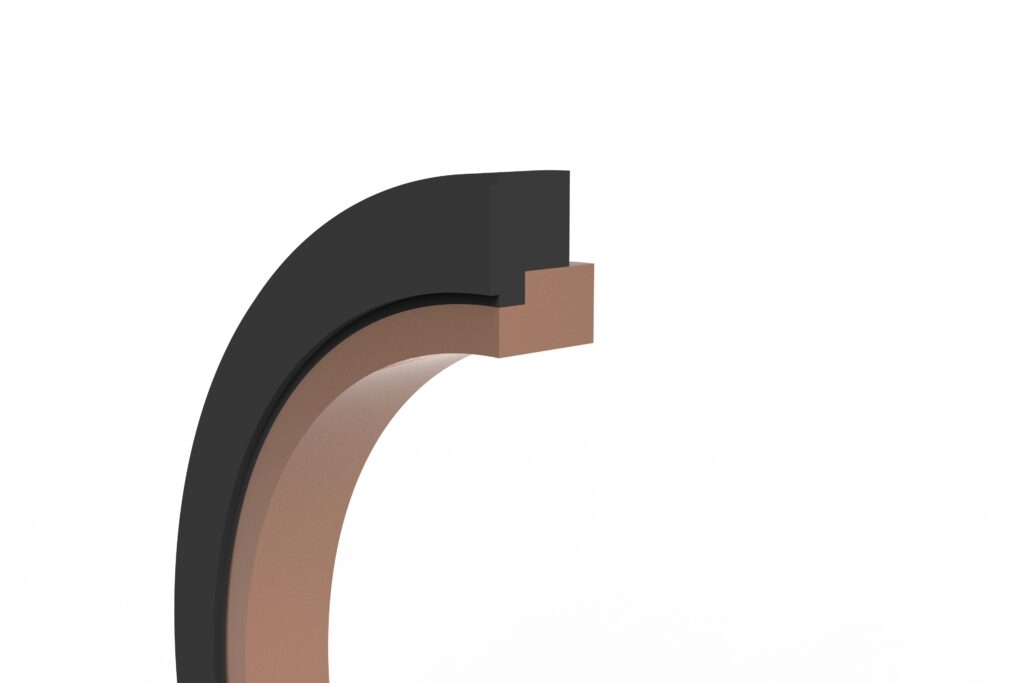

Steady Guards are buffer seals featuring integrated slide rings and a nitrile rubber (NBR) energizer paired with a PTFE slide ring.

The energizer ensures the slide ring remains securely positioned against the rod seal side of the housing. Traditional buffer seals can shift axially within the groove, pushing fluid into the rod seal groove during sudden pressure spikes, leading to rod seal failure. However, the Steady Guards design prevents any axial movement of the slide ring, offering superior protection for the rod seal in applications where conventional buffers fail. Grooves in the energizer’s outer diameter and notches in the slide ring’s front face facilitate pressure return to the system side.

Steady Guards are suitable for pressures up to 5,800 psi (40 MPa) in medium to heavy-duty applications and are available in inch sizes. For the most demanding large equipment applications, KC Seals can provide these profiles with polyamide (PA/Nylon) slide rings for enhanced extrusion and wear resistance.

| Specification | Details |

| Pressure Capacity | Maximum of 5,800 psi (40 MPa) |

| Operational Speed | 3.3 fps |

| Temperature Range | -40°C to +120°C | -40°F to +248°F |

| Material | Description | Temperature Range |

| Bronze PTFE | Bronze-filled PTFE, a composite material of PTFE and bronze powder, is known for its enhanced mechanical properties. The addition of bronze increases the hardness, compressive strength, and thermal conductivity of PTFE, making it suitable for high-load and high-temperature applications. This material is highly resistant to wear and exhibits excellent dimensional stability, which reduces creep and cold flow. Commonly used in bearings, wear rings, and hydraulic systems, bronze-filled PTFE provides superior performance in demanding environments | -200°C to +260°C | -328°F to 500°F |

| Material | Description | Temperature Range |

|---|---|---|

| NBR | Nitrile rubber, also known as NBR or Buna-N, is a synthetic rubber copolymer made from acrylonitrile and butadiene. It is renowned for its excellent resistance to oils, fuels, and other petroleum-based substances, making it ideal for automotive, aerospace, and industrial applications. NBR can withstand temperatures ranging from -40°C to 120°C, offering durability and flexibility. While it excels in oil and chemical resistance, it is less suitable for prolonged exposure to ozone and UV light. Nitrile rubber is widely used in manufacturing gaskets, seals, hoses, and O-rings due to its high tensile strength and abrasion resistance | -40°C to +120°C | -40°F to +248°F |

For comprehensive support on housing details or to explore potential solutions tailored to your application, we invite you to book a meeting with us