High-Performance Downhole Sealing

Book a meeting today and let's discuss your sealing project

Book a Meeting

Book a meeting today and let's discuss your sealing project

Book a Meeting

Well completions demand sealing solutions that can withstand some of the harshest downhole environments in the oilfield. From extreme pressures and temperatures to exposure to aggressive chemicals, every component must perform flawlessly to ensure well integrity, tool reliability, and efficient operations.

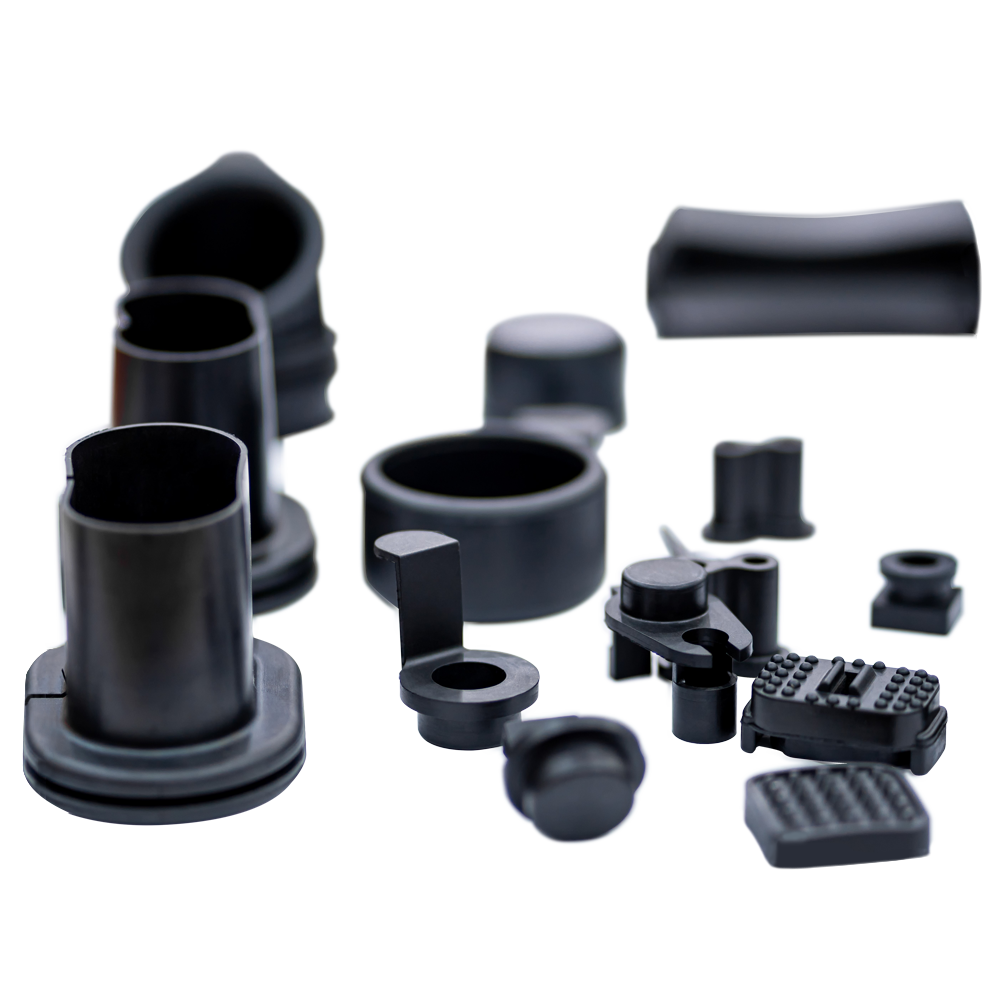

At KC Seals, we specialize in engineered sealing systems for a wide range of completion tools—supporting plug-and-perf systems, liner hangers, production packers, flow control devices, degradable frac plugs, and more. Our expertise in elastomers, thermoplastics, and thermosets ensures reliable performance in even the most demanding HPHT environments.

Plug & Perf Systems

Seals for reliable zonal isolation during hydraulic fracturing operations.

Liner Hangers

High-pressure, tight-clearance sealing using innovative packer designs for efficient wellbore anchoring.

Production Packers

Durable elastomeric seals that isolate production zones and prevent fluid migration.

Flow Control Devices

High-performance seals for sliding sleeves and other flow control components to maintain consistent pressure and flow rates.

Degradable Frac Plugs

Dissolvable elastomers that eliminate the need for milling or retrieval, reducing completion time and cost.

Below is a list of some of our most popular sealing products for completion tool equipment: