our four-point solution significantly reduces the risk of rubber fin fractures and debonding.

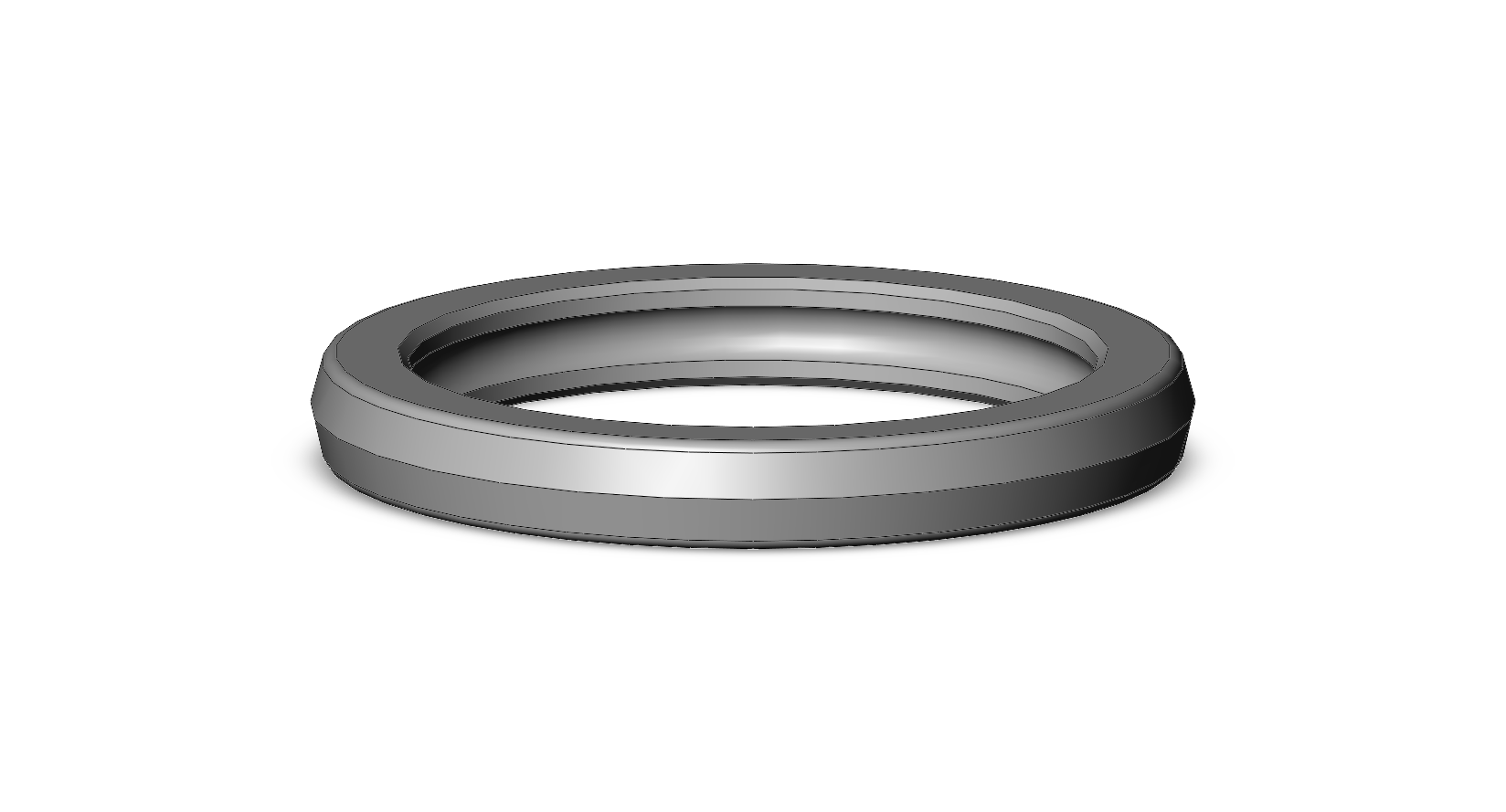

Centralizer Fins

our four-point solution significantly reduces the risk of rubber fin fractures and debonding.

After months of research and collaboration with drilling engineers, directional companies, rubber compounder’s and bonding agent suppliers, we were able to narrow down the primary reason why the rubber on fins fail: SWELL. Swell can produce too much interference between the fin and the tool carrier, increasing friction, compounding the swell issue and ultimately leading to fin fractures. When this happens, the fin loses its ability to keep the tool centred, creating lateral shock and potentially damaging the electronics and battery on the tool string. In addition, if the swell is bad enough, it can compromise the bond, and the rubber can rip off altogether, causing a whole host of issues, such as ending up in the impeller and damaging the RSS.

Much time and resources have gone into determining our four-point solution to fin fractures and debonding. And although these factors can significantly reduce the likelihood of fin failures, it is not a failsafe solution, as there is no escaping the aggressive nature of the application or the caustic ingredients within oil-based muds. However, these four factors can drastically increase fin performance and greatly reduce the risk of potential downtime caused by fin failures.

Download our infographic for more information: Centralizer fin infographic

All parts are measured on our Zeiss O-Machine and or Keyence CMM, which utilize optical and contact measurement technology in a comprehensive analysis. The O-Machine includes multi-sensor coordinate measuring, white light sensors for non-contact assessments and extremely accurate 3D scanners.

We follow AQL 2.5 levels 1 and 2 sample size quantities, and all molded parts are manufactured to RMA A2 tolerances.

Our rubber and plastic materials supply is diversified amongst the top compounders in North America. Each polymer has been qualified to meet typical exploration and production well conditions, including mechanical, tribological, thermal, and specific immersive properties.

You’ve made it this far, but we know there is still more to discuss. Click on the book a meeting button below and we can discuss over a phone or video call. You can also email us at info@kcseals.ca.