High Pressure High Temperature V Sealing Stacks

V-Packing

High Pressure High Temperature V Sealing Stacks

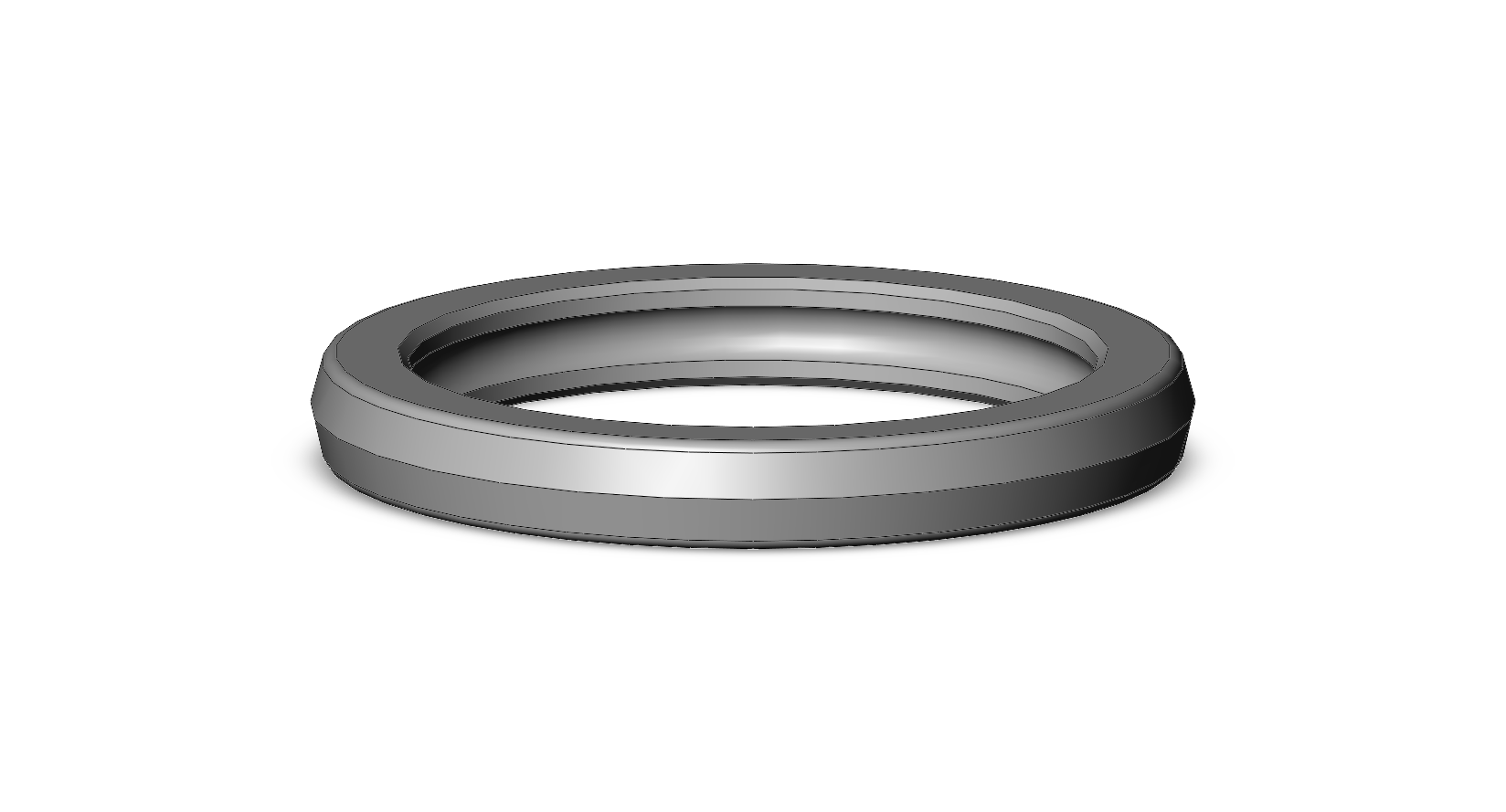

V-Packing is an assembly made up of a nest of Chevron rings comprising a top adapter or anti-extrusion ring, Inner V-Rings and a bottom adapter. In the assembly, the energizing axial force is transferred between the individual packing rings so that each ring is pressed into positive contact with the mating hardware surface. Special material grades are available for a large variety of working conditions.

The top adapter or anti-extrusion ring is manufactured from a high modulus plastic, typically PEEK™, to resist extrusion. This component supports the Vee Rings, providing stability and extrusion resistance.

Inner V-Rings are typically made from filled PTFE materials; although, depending on the application, elastomers can be used as well to offer better sealing efficiency.

The bottom adapter ring is manufactured from PEEK™ or glass-filled PTFE. The function of this component is to ensure a uniform pressure distribution.

Operating Pressure | Up to 20,000 psi |

Speed | Up to 3.3 ft/s depending on the material |

Temperature Range | -45 °C to +260 °C / |

| VEE-RING STACK HEIGHTS WITH MIDDLE, TOP, AND BOTTOM ADAPTERS | ||||||

|---|---|---|---|---|---|---|

| Mid Piece Number | Packing Cross Section | |||||

| 3/16 | 1/4 | 5/16 | 3/8 | 7/16 | 1/2 | |

| 3 | 0.630 | 0.750 | 0.875 | 1.000 | 1.081 | 1.250 |

| 4 | 0.740 | 0.875 | 1.031 | 1.188 | 1.300 | 1.500 |

| 5 | 0.850 | 1.000 | 1.187 | 1.375 | 1.517 | 1.750 |

| 6 | 0.960 | 1.125 | 1.344 | 1.562 | 1.735 | 2.000 |

| Rubber Application Pressure(PSI) | Fabric Reinforced Application Pressure(PSI) | Number Required |

|---|---|---|

| 500 to 1,000 | 500 to 1500 | 3 |

| 1000 to 1200 | 1,500 to 3,000 | 4 |

| 2000 to 3000 | 3,000 to 5,000 | 5 |

| 3000 to 5000 | 5,000 to 10,000 | 6 |

| 5000 over | 10,000 and over | 7 |

All parts are measured on our Zeiss O-Machine and or Keyence CMM, which utilize optical and contact measurement technology in a comprehensive analysis. The O-Machine includes multi-sensor coordinate measuring, white light sensors for non-contact assessments and extremely accurate 3D scanners.

We follow AQL 2.5 levels 1 and 2 sample size quantities, and all molded parts are manufactured to RMA A2 tolerances.

Our rubber and plastic materials supply is diversified amongst the top compounders in North America. Each polymer has been qualified to meet typical exploration and production well conditions, including mechanical, tribological, thermal, and specific immersive properties.

You’ve made it this far, but we know there is still more to discuss. Click on the book a meeting button below to easily setup up a date and time to talk more about your project. You can also email us at info@kcseals.ca