Sealing Solutions for Reliable Production

Book a meeting today and let's discuss your sealing project

Book a Meeting

Book a meeting today and let's discuss your sealing project

Book a Meeting

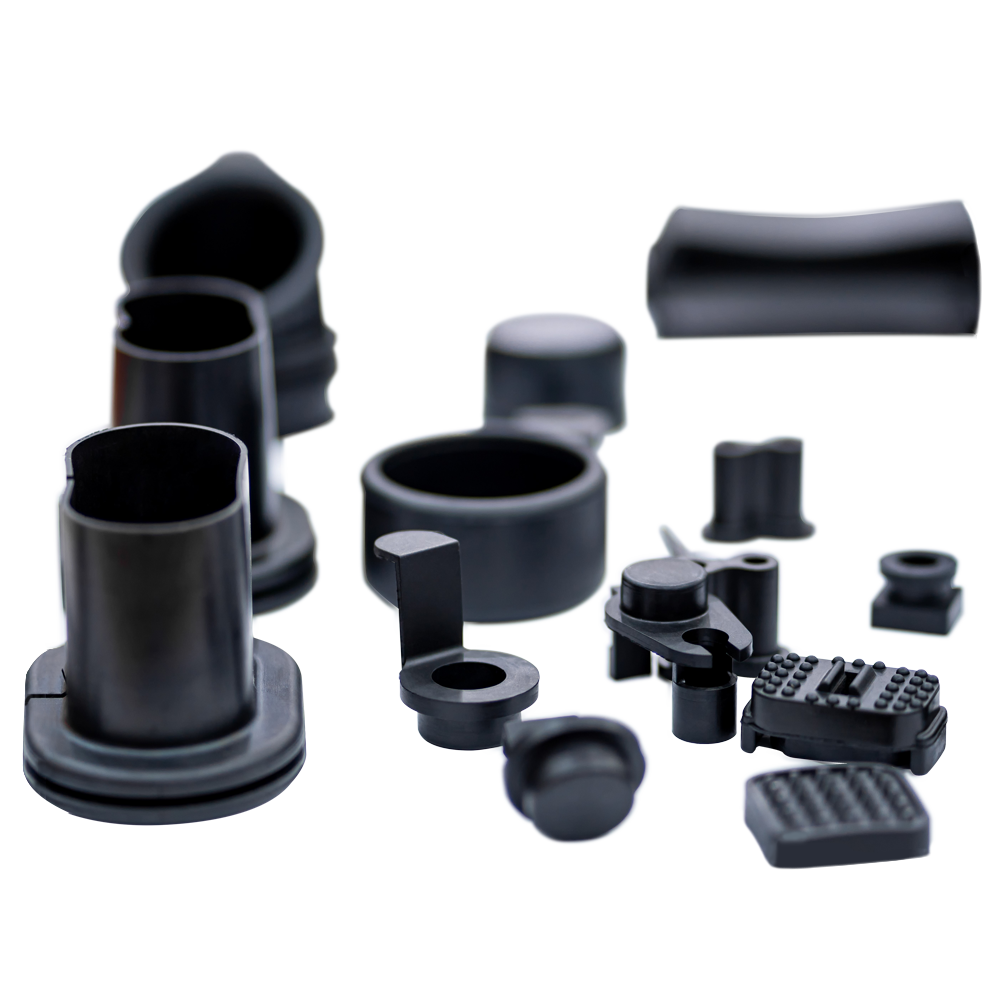

As a trusted leader in engineered sealing systems, KC Seals delivers high-performance solutions across the upstream and midstream sectors—including artificial lift, well intervention, gas compression, and production optimization. Our mission-critical components are built to withstand the harshest environments, combining advanced materials, innovative geometries, and industry-leading certifications to solve the industry’s most complex sealing challenges.

Below is a list of specific challenges we’ve helped solve for companies manufacturing production tools and equipment- each tied to real-world issues around performance, reliability, and supply chain efficiency.

Challenges:

VFD-induced heat in ESPs

Scale buildup in gas lift valves

Hydrogen embrittlement in H₂S-rich wells

Our Solutions:

ESP Motor Protectors: FFKM seals (e.g., Simriz® 498) engineered for up to 300°C thermal stability in SAGD and steam-assisted lift systems

Gas Lift Valves: PTFE seals with abrasion-resistant geometries to combat scale and extend tool life

Corrosion Resistance: NORSOK M-710 approved HNBR and FKM compounds for sour gas applications with high H₂S exposure

Challenges:

Sustained casing pressure

Water breakthrough

Degraded or failed production packers

Our Solutions:

Sand Control Systems: High-expansion elastomers for effective sealing in gravel pack and perforation zones

Packer Element Remediation: API 11D1-certified elements with rapid gas decompression (RGD) resistance for extended downhole performance

Challenges:

Contaminant precipitation

Emission control and seal wear

Our Solutions:

Contaminant Mitigation: Super-coalescers paired with RGD-resistant elastomers for cleaner, more efficient operation

High-Pressure Sealing: Custom FS and T-Seals rated for 20,000 psi, ideal for rough casing and fluctuating gas loads

We engineer and qualify our materials to withstand the toughest environments:

Elastomers:

HNBR – excellent resistance to H₂S and hydrocarbon fluids

FFKM – reliable sealing up to 315°C

EPDM – ideal for steam and CO₂ service

Thermoplastics:

Glass-filled PEEK – optimized for abrasive, multiphase flow

UHMW-PE – enhanced wear resistance and mechanical strength

API 11D1 V3/V0, ISO 14310, and NORSOK M-710 compliant products

Collaborative development programs with operators to engineer custom sealing solutions for reservoir-specific challenges, including high-CO₂ EOR environments